Basement underpinning is a structural process designed to reinforce, stabilize, and secure an existing foundation by extending it to a deeper level. It’s a meticulous, safety-driven method that allows homeowners to gain extra ceiling height, create usable living space, and correct foundation weaknesses without compromising structural integrity.

Key Steps in the Underpinning Process

| Stage | Description | Purpose |

|---|---|---|

| Structural Assessment | Engineers inspect soil conditions, existing footings, and load paths. | Identify weaknesses and design safe reinforcement. |

| Permitting & Planning | Detailed engineering drawings and permits are obtained. | Ensure compliance with municipal and building codes. |

| Excavation in Sections | Soil is excavated beneath the existing foundation in controlled stages. | Maintain foundation stability during lowering. |

| Concrete Pouring & Curing | Concrete is placed under each section and allowed to cure fully. | Form the new, deeper foundation footing. |

| Load Transfer & Backfilling | The structure’s weight is gradually shifted onto the new footing. | Reinstate full structural support. |

| Waterproofing & Drainage | Perimeter drains and membranes are installed. | Protect against moisture and hydrostatic pressure. |

| Inspection & Verification | Inspectors confirm structural soundness, alignment, and safety. | Certify that the underpinning meets all quality standards. |

Why Safety and Inspections Matter:

- Continuous Monitoring: Engineers track ground movement and concrete performance throughout the process.

- Controlled Sequencing: Work progresses in zones to prevent shifting or settlement.

- Compliance Assurance: Municipal inspections verify adherence to design, safety, and building codes.

- Long-Term Stability: Proper inspection ensures the new foundation remains strong for decades.

By following this structured approach, the underpinning process not only enhances foundation strength but also creates a secure, level, and code-approved basement space ready for finishing or conversion.

What Does the Underpinning Process Involve?

The underpinning process involves strengthening and deepening an existing foundation to restore or enhance structural stability. It’s used when the original foundation can no longer safely support the load due to soil movement, added weight from extensions, or deterioration over time. The process is completed in carefully engineered phases to prevent structural stress and ensure full safety throughout.

How Does Underpinning Strengthen and Stabilize Existing Foundations?

Underpinning reinforces the foundation by transferring the building’s weight onto a new, deeper, and stronger base. Engineers excavate sections beneath the existing footing, pour high-strength concrete, and allow it to cure before proceeding to the next stage. This creates a continuous, reinforced support that stabilizes the entire structure.

Here are the Underpinning Strengthen and Stabilize Existing Foundations Key outcomes:

- Restores foundation strength in unstable soil conditions

- Corrects uneven settlement or structural sagging

- Extends foundation depth for additional load-bearing capacity

- Provides long-term stability for property extensions or added floors

What Are the Core Stages in a Standard Underpinning Sequence?

The underpinning process follows a structured, methodical sequence to ensure the building remains stable throughout every phase of work. Each stage is carefully planned and supervised by engineers to maintain safety, precision, and compliance with building codes. The process begins with a detailed inspection and design phase, followed by sectional excavation and concrete placement. Each section is completed and cured before the next begins, preventing uneven load transfer or settlement. Once the new footing is set, the structure is reloaded and the site is restored, leaving a stronger, deeper, and more reliable foundation.

Here’s an overview of the main stages involved in a standard underpinning sequence:

| Stage | Action | Objective |

|---|---|---|

| 1. Assessment | Engineers inspect the site, review soil conditions, and identify foundation weaknesses. | Determine the appropriate underpinning method and scope of work. |

| 2. Design & Permits | Structural drawings and calculations are prepared and submitted for approval. | Ensure safety standards and regulatory compliance. |

| 3. Sectional Excavation | Small sections beneath the existing foundation are excavated in sequence. | Maintain stability and control during soil removal. |

| 4. Concrete Placement | High-strength concrete is poured into each excavated pit and reinforced as required. | Form a new foundation that supports beneath the original footing. |

| 5. Curing & Load Transfer | Concrete is left to cure before transferring the structural load gradually. | Reinstate full support for the strengthened foundation. |

| 6. Finishing & Backfill | Excavated areas are filled, compacted, and levelled; the site is restored. | Complete stabilization and prepare the basement for flooring or finishing. |

This sequential approach ensures that each underpinning stage builds safely upon the last, maintaining structural integrity while delivering a deeper, more resilient foundation ready for long-term use.

Why Is Section-by-Section Excavation Critical for Foundation Safety?

Excavating the entire foundation at once can cause the structure to collapse or shift. The section-by-section method—also known as pin underpinning—ensures only a small part of the footing is exposed at any given time. This maintains continuous support, allowing the rest of the foundation to bear the load safely while work progresses.

What Materials Are Commonly Used in Modern Underpinning Methods?

Modern underpinning techniques use a variety of materials chosen for strength, durability, and compatibility with soil conditions.

Common materials include:

- Concrete: The most widely used material for mass pour or beam-and-base underpinning.

- Steel Piles: Used in screw pile or mini-pile systems for deeper or unstable soils.

- Grout or Resin Compounds: Injected into weak soils to fill voids and enhance load-bearing capacity.

- Reinforcement Bars (Rebar): Embedded in concrete to increase tensile strength.

The choice of material depends on factors such as soil type, building load, environmental conditions, and project budget.

The underpinning process is both structural and strategic, combining precision engineering with safety-led practices to strengthen the foundation and secure the building for decades to come.

How Is the Site Prepared Before Underpinning Begins?

Site preparation is a crucial first phase in the underpinning process. Before any excavation or foundation work begins, engineers and contractors carry out detailed evaluations to ensure the site conditions are safe, stable, and compliant with construction standards. Preparation includes assessing structural risks, reviewing soil performance, identifying hidden utilities, and confirming that all safety measures are in place. Proper groundwork ensures that the underpinning can proceed without causing settlement, vibration damage, or service disruptions to the property or neighbouring structures.

What Pre-Construction Inspections Determine the Need for Underpinning?

Before underpinning is approved, engineers conduct a thorough inspection of both the structure and the surrounding environment. The purpose of these inspections is to establish whether the existing foundation can continue to safely support the building and to identify any early warning signs of instability.

Key inspection activities include:

- Visual assessment: Detects wall cracks, floor gaps, leaning chimneys, or sticking doors that indicate settlement.

- Structural survey: Measures foundation depth, material condition, and load paths through the structure.

- Soil movement history: Reviews site records and nearby construction activities for potential ground disturbance.

- Moisture and drainage review: Checks for water intrusion or hydrostatic pressure affecting foundation walls.

These inspections help determine whether full underpinning, partial reinforcement, or an alternative method like benching is the safest solution.

How Is the Load-Bearing Capacity of the Soil Assessed?

Soil strength directly determines the success of an underpinning project. Geotechnical engineers perform detailed soil investigations to understand how the ground will respond to additional weight and excavation.

Typical soil assessment methods:

- Borehole sampling: Extracts deep soil samples to examine layers, density, and water content.

- Standard penetration testing (SPT): Measures resistance of soil to penetration, indicating load-bearing strength.

- Laboratory analysis: Tests moisture content, clay reactivity, and compaction characteristics.

- Groundwater monitoring: Evaluates seasonal water fluctuations that may affect stability.

This data guides the underpinning design, ensuring the new foundation rests on stable strata with adequate load-bearing capacity.

Why Must Utilities and Drainage Be Identified Before Excavation?

Before excavation begins, contractors must locate all underground utilities such as gas lines, water mains, sewers, and electrical conduits. Hitting or damaging any of these systems can lead to severe safety hazards, property damage, or costly project delays.

Reasons for mapping utilities and drainage:

- Worker safety: Prevents accidents from ruptured gas or electrical lines.

- Structural protection: Avoids unintentional weakening of nearby service trenches or retaining walls.

- Drainage control: Ensures existing systems remain functional during and after underpinning.

- Planning efficiency: Helps integrate waterproofing and sump pump designs into the new layout.

Identifying utilities and drainage early allows engineers to coordinate excavation paths safely and protect essential infrastructure throughout the underpinning process.

Comprehensive site preparation—combining inspection, soil testing, and service mapping—forms the foundation of a safe, compliant, and well-engineered underpinning project.

What Are the Key Steps in the Underpinning Process?

The underpinning process unfolds through a series of carefully sequenced steps that ensure stability, safety, and precision at every stage. Each action builds on the previous one, allowing the structure to remain supported as the foundation is deepened and reinforced. This step-by-step approach is vital for maintaining balance, avoiding sudden shifts, and ensuring the new footing integrates seamlessly with the existing structure.

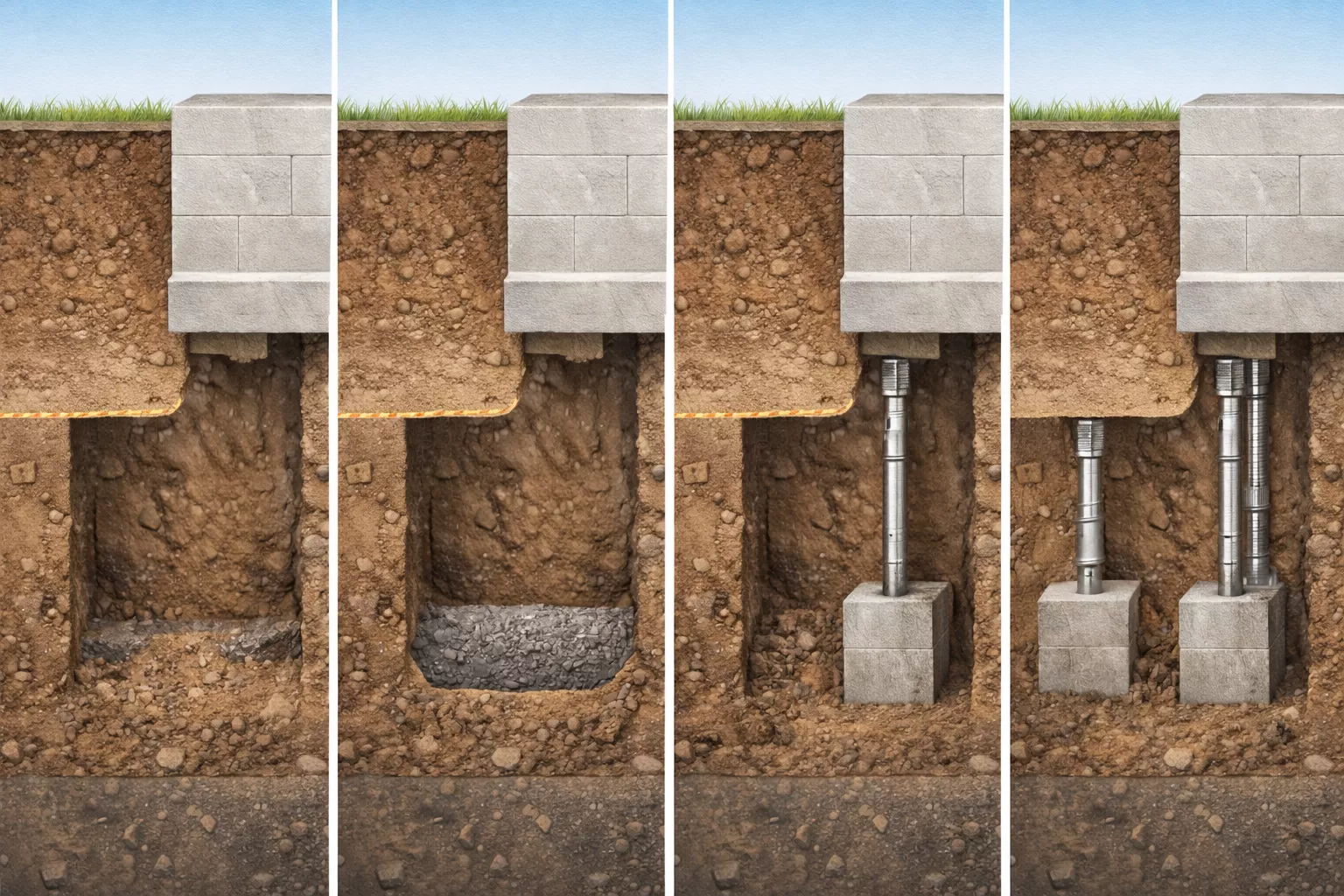

How Is the Foundation Excavation Performed in Stages?

Excavation is the first and most critical step in underpinning. Instead of removing all soil at once, the process is performed in small, alternating sections, known as “pins” or “bays.” Each section is excavated beneath the existing foundation to a predetermined depth, allowing the rest of the structure to remain supported.

Key points of staged excavation:

- Excavations are typically 3–4 feet wide and spaced evenly along the foundation.

- Adjacent sections are never opened simultaneously, preventing load imbalance.

- Temporary supports, such as jacks or props, are installed to stabilize walls during excavation.

- Each completed section is inspected before moving to the next.

This incremental method ensures that structural stability is maintained throughout the process and that no sudden movement or cracking occurs in the existing foundation.

What Role Do Shuttering and Reinforcement Play During Underpinning?

Once excavation is complete in each section, formwork (also called shuttering) is constructed to shape and contain the concrete. Steel reinforcement bars (rebar) are then installed inside the formwork to improve tensile strength and bond the new foundation securely to the existing footing.

Importance of shuttering and reinforcement:

- Prevents soil collapse by containing wet concrete during placement.

- Ensures consistent foundation dimensions and alignment.

- Strengthens the joint between new and existing structural elements.

- Reduces the risk of settlement or cracking under future loads.

Proper shuttering and reinforcement are essential for creating a uniform, durable, and load-resistant foundation structure.

How Is Concrete Placed and Cured to Support Existing Structures?

High-strength concrete is poured into each shuttered section, filling the excavated void beneath the footing. The concrete must be placed evenly and compacted to eliminate air pockets that could weaken the structure.

Concrete curing process:

- Concrete is left to cure for at least 48–72 hours per section before proceeding.

- Moisture levels are controlled to prevent shrinkage or cracking.

- After curing, formwork is removed and inspected for defects.

- The process is repeated in adjacent sections until the entire perimeter is underpinned.

Once all sections have been completed, the new underpinning forms a continuous, reinforced foundation layer capable of bearing the entire structural load.

When Is Structural Load Transfer Safely Achieved?

Load transfer is the final stage of underpinning and represents the point at which the weight of the structure is fully supported by the new, deeper foundation. This is done gradually and only after the concrete in all underpinning sections has reached the required strength.

Steps for safe load transfer:

- Engineers verify curing strength using compression tests or inspection reports.

- The temporary supports are removed incrementally to distribute loads evenly.

- Structural monitoring ensures no unexpected movement occurs during transfer.

- Once confirmed stable, backfilling and waterproofing complete the process.

At this stage, the building’s foundation is officially stabilized and strengthened, ready for long-term performance and any planned basement finishing or expansion.

Through this stepwise, controlled sequence—excavation, reinforcement, concreting, and load transfer—the underpinning process delivers a secure, reinforced foundation that meets both engineering and safety standards.

How Do Engineers Ensure Accuracy During Each Underpinning Phase?

Accuracy is the foundation of a safe underpinning project. Every phase, from excavation to load transfer, requires continuous monitoring and precision control to prevent differential settlement, cracking, or misalignment. Engineers apply advanced measurement systems, detailed inspection schedules, and a methodical rate of progress to ensure that every action maintains the building’s balance and complies with design tolerances.

Maintaining precision throughout the process guarantees not only structural integrity but also long-term performance and safety for the property.

What Monitoring Systems Track Foundation Movement or Settlement?

During underpinning, engineers deploy structural monitoring systems to measure even the smallest shifts or settlements in real time. These tools allow early detection of any movement that could indicate instability or uneven load distribution.

Common monitoring methods include:

- Settlement markers: Installed along foundation walls to record vertical movement over time.

- Crack gauges: Measure any widening or propagation of cracks on interior or exterior walls.

- Laser levelling and total stations: Provide highly accurate elevation data across multiple points.

- Tilt sensors and inclinometers: Detect minute angular displacements or lateral movement.

The data collected from these systems is compared with design tolerances, enabling engineers to respond quickly if deviations occur, ensuring full control of the underpinning operation.

How Often Are Measurements Taken to Verify Structural Stability?

Measurement frequency depends on site complexity, soil type, and the underpinning method used. However, monitoring is generally performed continuously during active phases and at regular intervals after each section is completed.

Typical measurement schedule:

- Daily readings during excavation and concrete curing stages.

- Weekly or bi-weekly checks as subsequent sections are completed.

- Post-construction monitoring for several months to confirm stability.

Each reading is documented in a structural log reviewed by engineers and inspectors. Consistent tracking ensures that even subtle settlement trends are caught early and addressed before they escalate.

Why Is Incremental Progress Essential for Risk Control?

Underpinning is never rushed. Incremental progress is a safety requirement designed to minimize risk to both the structure and the crew. Excavating or loading too quickly can cause stress imbalances, leading to wall cracking, uneven settlement, or even partial collapse.

Reasons incremental pacing is critical:

- Ensures concrete in each section fully cures before new loads are applied.

- Allows engineers to analyze monitoring data and adjust sequencing if necessary.

- Reduces the risk of structural shock or vibration affecting stability.

- Provides inspection checkpoints for verifying alignment and compliance.

By advancing methodically—one section, one test, one verification at a time—engineers maintain complete control of the process, guaranteeing accuracy, safety, and durability in every underpinning project.

What Safety Measures Govern the Underpinning Process?

Safety governs every aspect of the underpinning process, from initial excavation to final load transfer. Because work occurs beneath active structures, strict adherence to engineering standards, protective systems, and regulatory guidelines is essential. Contractors and engineers collaborate under clearly defined safety protocols that safeguard workers, occupants, and neighbouring properties.

A comprehensive safety plan covers environmental hazards, ground stability, and confined-space operations, ensuring that every underpinning project proceeds without incident while maintaining full compliance with building and occupational safety codes.

How Do Safety Standards Minimize Risks to Workers and Residents?

Underpinning involves high-risk activities such as excavation below existing foundations, concrete work in confined spaces, and structural load management. To mitigate these risks, industry standards and safety codes are strictly enforced throughout the project.

Key safety practices include:

- Engineering sign-off before excavation begins, verifying the design’s structural safety.

- Sequential underpinning, ensuring load-bearing continuity at all times.

- Daily site safety inspections to identify hazards before work starts.

- Emergency preparedness plans for potential ground movement or water infiltration.

Following safety standards set by organizations such as the Canadian Centre for Occupational Health and Safety (CCOHS) and local building authorities helps protect both the construction team and nearby residents.

What Protective Systems Prevent Ground Collapse or Water Ingress?

Excavation beneath a foundation introduces risks of soil collapse, lateral pressure, and groundwater intrusion. Protective systems are installed to maintain soil stability and safeguard the workspace.

Protective measures include:

- Shoring and bracing systems to reinforce excavated walls.

- Sheet piling or soldier piles in deep or unstable soils.

- Weeping tiles and sump pumps to manage groundwater buildup.

- Waterproof membranes and drainage mats to prevent hydrostatic pressure after backfilling.

- Temporary retaining walls or trench boxes for added excavation support.

These systems collectively preserve both the integrity of the structure above and the safety of the workers below.

How Are Confined-Space Hazards Managed During Excavation?

Underpinning often takes place in tight, enclosed environments with limited airflow and access. Managing confined-space risks is critical for worker safety and project compliance.

Confined-space safety controls include:

- Continuous ventilation to prevent the buildup of dust, fumes, or gases.

- Gas detection monitors to ensure safe oxygen levels.

- Access ladders and egress points in every working zone.

- Trained spotters or safety attendants stationed outside confined spaces.

- Permit-to-work systems that document and control entry and exit.

Proper lighting and communication systems are also maintained to ensure visibility and coordination throughout excavation.

What PPE and Site Protocols Are Mandatory for Underpinning Crews?

Personal Protective Equipment (PPE) and disciplined site management are non-negotiable elements of underpinning safety. Every worker must be properly equipped and trained to operate in a potentially unstable environment.

Standard PPE and site protocols include:

- Hard hats, steel-toe boots, and high-visibility vests for general protection.

- Dust masks or respirators are required during excavation and concrete mixing.

- Safety gloves and eye protection for handling rebar and wet concrete.

- Hearing protection when using power tools or cutting machinery.

- Clear access routes and signage to control movement around excavation zones.

- Daily safety briefings and toolbox talks to reinforce risk awareness.

By maintaining these safety standards and enforcing strict supervision, underpinning projects achieve zero-compromise protection for both workers and residents, ensuring the entire process remains stable, compliant, and incident-free.

How Are Quality and Compliance Verified Through Inspections?

Quality control and compliance verification are essential stages in the underpinning process. Since the work directly affects the structural safety of a building, every phase—from excavation to final load transfer—is inspected under the supervision of qualified professionals and municipal authorities. These inspections confirm that the underpinning meets all engineering specifications, safety standards, and building code requirements before the structure is reloaded or occupied.

The goal is not only to confirm that the foundation is secure but also to ensure that each element of the work complies with both design intent and legal obligations under local construction regulations.

Who Conducts Inspections During and After the Underpinning Process?

Inspections are carried out by a combination of licensed engineers, building officials, and site supervisors who oversee the quality and safety of every stage.

Key inspection personnel include:

- Structural engineer: Reviews the underpinning design, verifies concrete curing times, and ensures that load transfer follows approved calculations.

- Geotechnical engineer: Monitors soil stability and confirms that the new foundation rests on suitable strata.

- Building control officer (municipal inspector): Ensures compliance with local building codes and permit conditions.

- Site supervisor or foreman: Maintains daily quality logs, safety records, and coordinates inspections.

Inspections occur at multiple stages—before excavation, after each pour, and at completion—to ensure the project remains within design and safety parameters.

What Structural Tests Confirm That the Underpinning Meets the Design Load Criteria?

To verify that the new underpinning can safely bear the intended loads, several structural and material tests are conducted both during and after construction. These tests measure strength, durability, and overall performance.

Common structural tests include:

- Concrete compressive strength tests: Laboratory testing of core samples ensures the concrete has reached the required design strength.

- Load-bearing tests: Confirm that the new foundation adequately supports the weight transferred from the existing structure.

- Reinforcement inspection: Verifies that steel rebar placement and cover depth meet engineering drawings.

- Settlement and alignment checks: Detect any minor deflection or differential movement after load transfer.

- Waterproofing verification: Ensures membranes and drainage systems are properly sealed and functional.

These evaluations collectively guarantee that the underpinning performs as intended and will remain stable under long-term conditions.

How Are Inspection Reports Documented for Building Control Approval?

Every inspection, test, and verification is formally documented and submitted for building control approval. Proper documentation ensures transparency, traceability, and legal compliance.

Typical reporting workflow:

- Inspection logs: Record details of each completed underpinning section, including date, dimensions, and materials used.

- Engineer certification reports: Signed confirmation that works meet the design and structural standards.

- Photographic records: Visual evidence of excavation stages, reinforcement placement, and completed pours.

- Test results and compliance certificates: Include laboratory findings, curing reports, and material quality data.

- Final approval package: Submitted to municipal building control for review and issuance of compliance confirmation.

Once approved, the documentation becomes part of the property’s permanent building record, demonstrating that the underpinning was executed safely, inspected rigorously, and certified for structural integrity.

Through these meticulous inspections and reporting procedures, underpinning projects maintain the highest standards of quality assurance—delivering a foundation that is both technically sound and legally compliant.

How Does Inspection Data Influence Long-Term Foundation Performance?

Inspection data collected during and after the underpinning process serve as the foundation’s ongoing health record. It provides a measurable history of performance indicators—such as settlement rates, moisture readings, and load distribution—that engineers use to confirm long-term stability. Properly analyzed inspection data helps detect minor shifts or weaknesses early, allowing timely maintenance before issues escalate.

This long-term monitoring ensures that the new underpinning continues to perform as designed, protecting both the structural integrity and property value of the building for decades.

Why Is Post-Underpinning Monitoring Essential for Stability Assurance?

Once the underpinning process is complete, the structure enters a monitoring phase to verify that the foundation remains stable under real-world conditions. Post-underpinning monitoring identifies any delayed settlement, soil movement, or water infiltration that might affect long-term performance.

Key monitoring practices include:

- Periodic settlement readings using reference points or levelling benchmarks.

- Crack and deflection tracking to ensure walls and slabs remain stable.

- Moisture and drainage checks to monitor hydrostatic pressure or leaks.

- Engineer inspections at scheduled intervals to compare performance data with original design criteria.

Consistent post-construction monitoring ensures the underpinning maintains full structural strength and prevents minor issues from developing into costly structural repairs.

What Signs Indicate Successful Underpinning Performance Over Time?

The success of an underpinning project becomes evident through consistent performance indicators that confirm the structure’s stability and durability.

Positive signs of long-term underpinning success include:

- No measurable settlement beyond acceptable engineering tolerances.

- Stable walls and floors with no new or expanding cracks.

- Dry, well-drained basement conditions indicate effective waterproofing.

- Smooth operation of doors and windows, confirming no differential movement.

- Stable alignment of exterior features, such as brickwork or chimneys.

Regularly reviewing inspection data against these indicators allows engineers and property owners to verify that the underpinning continues to perform effectively, delivering the intended strength, safety, and longevity for the entire structure.

Through continuous inspection and data-driven evaluation, the foundation’s long-term reliability is not left to chance—it’s measured, recorded, and assured through ongoing performance monitoring.

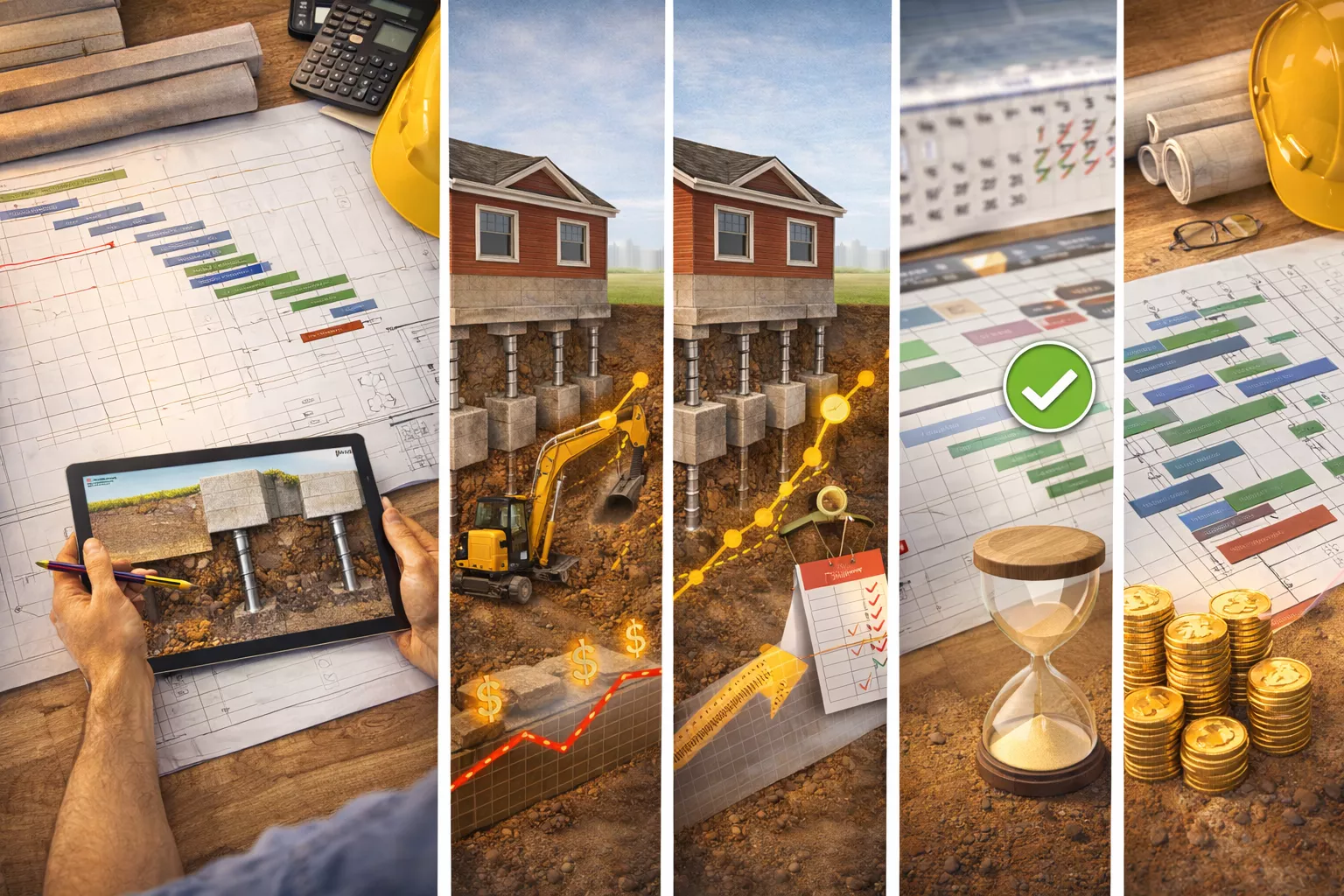

How Does Project Planning Affect Cost and Duration of Underpinning?

Effective project planning is the foundation of a cost-efficient and timely underpinning project. Because underpinning involves multiple technical stages—assessment, excavation, concrete work, waterproofing, and inspection—proper scheduling and budgeting are essential to avoid delays, rework, or unplanned expenses. A well-structured plan accounts for soil type, access limitations, permit timelines, and structural complexity, allowing the process to proceed smoothly from start to finish.

Comprehensive planning ensures that the underpinning not only strengthens the foundation but also delivers predictable outcomes in terms of time, cost, and performance.

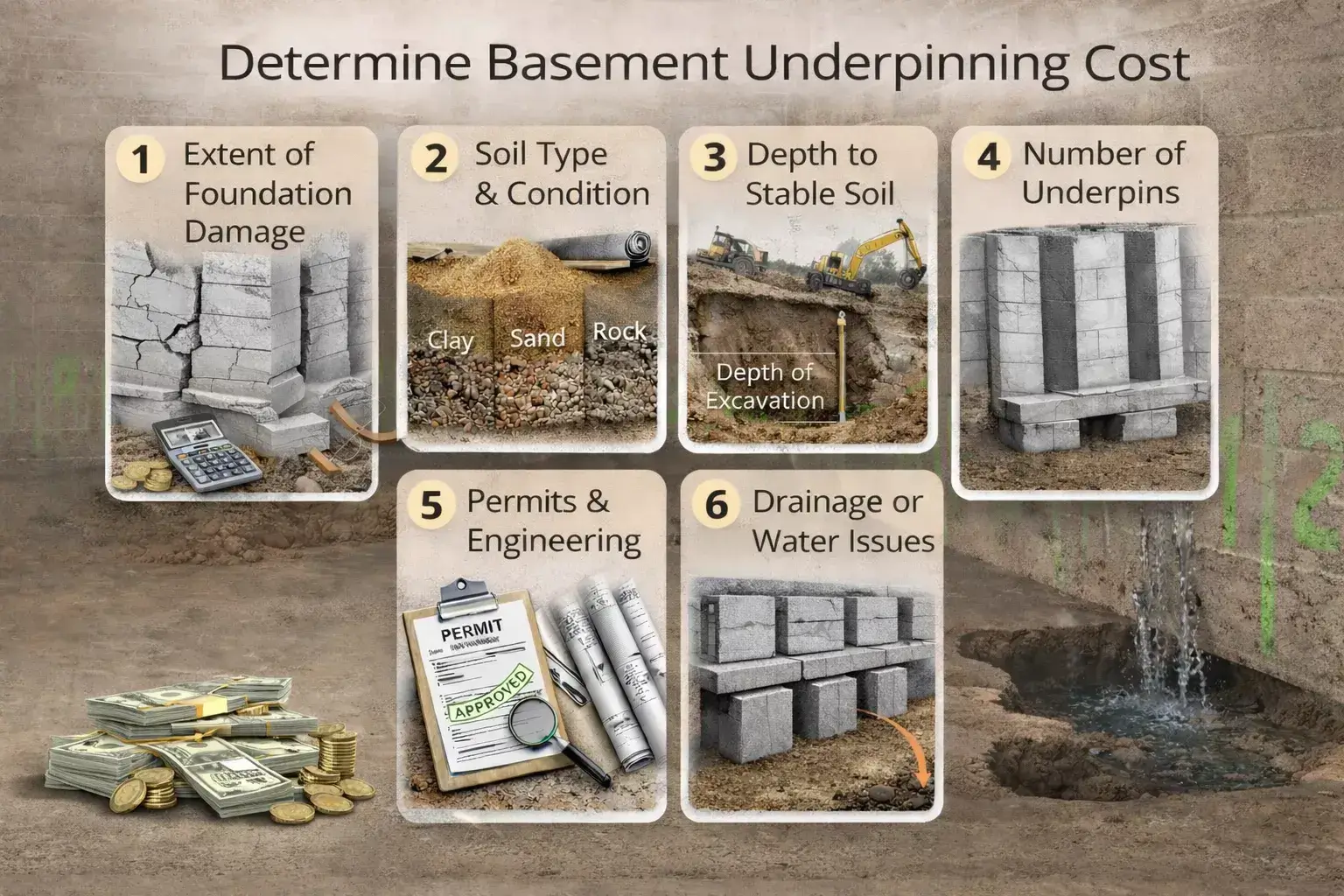

What Variables Influence Underpinning Timeframes and Project Budgets?

Several factors directly determine how long an underpinning project takes and how much it costs. Each variable interacts with the others, making accurate early assessment and realistic scheduling critical.

Primary variables include:

- Basement size and excavation depth: Larger or deeper basements require more excavation, reinforcement, and concrete volume, extending project duration.

- Soil conditions: Reactive or unstable soils demand additional testing, shoring, or piling, increasing cost and time.

- Structural complexity: Older or compromised foundations may require extra reinforcement or staged load transfers.

- Access and logistics: Limited site access or restricted equipment movement can slow material delivery and excavation.

- Permit and inspection delays: Municipal approval processes can add several weeks before work can begin.

- Additional works: Integrating waterproofing, plumbing, or drainage upgrades increases both cost and timeframe.

Clear communication between engineers, contractors, and inspectors at the planning stage helps anticipate these factors and minimize overruns.

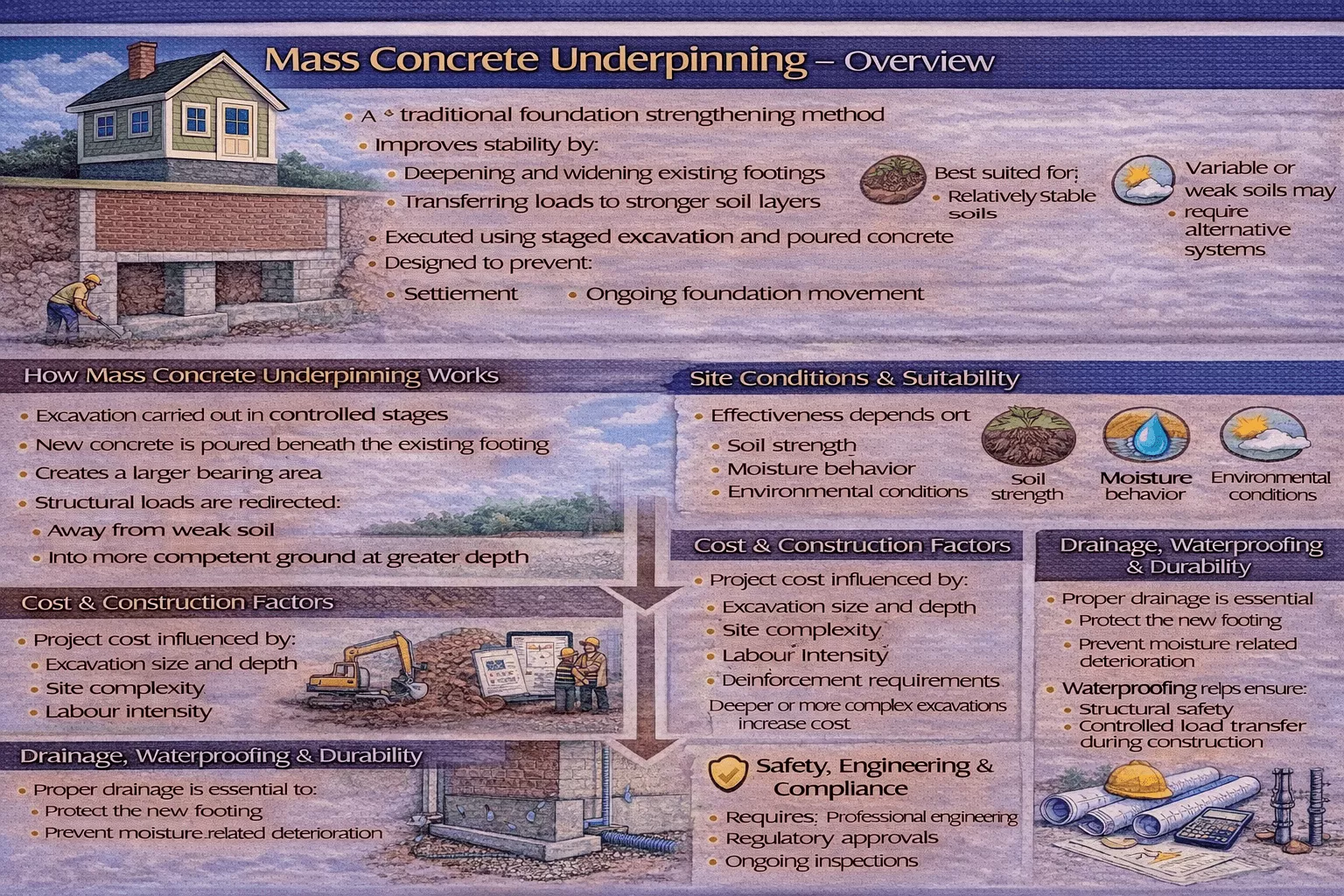

Why Does the Chosen Underpinning Method Affect Overall Cost Efficiency?

The underpinning method selected for a project has a direct impact on both cost and efficiency. Each technique—such as mass concrete underpinning, beam-and-base systems, screw piles, or resin injection—carries different material, labour, and time requirements.

Cost-efficiency considerations:

- Mass concrete underpinning: Typically, the most economical for shallow foundations, but slower due to staged excavation and curing.

- Beam-and-base systems: Faster than traditional methods but require more engineering precision and higher material costs.

- Screw piles or mini-piles: Offer rapid installation with minimal disruption, but increase costs due to specialist equipment.

- Resin injection: Ideal for targeted soil stabilization; cost-effective for localized issues but unsuitable for major lowering.

Selecting the most appropriate method based on soil behaviour, structural load, and budget objectives ensures that time and money are used efficiently without compromising safety or durability.

Through strategic planning and method selection, underpinning projects achieve an optimal balance between time, cost, and long-term performance, ensuring the process remains both structurally sound and economically viable.

How Do Structural Conditions Affect the Need for Underpinning?

The decision to undertake underpinning depends primarily on the structural behaviour of a building and the condition of the soil beneath it. Before any work begins, engineers analyze visible damage, monitor movement trends, and assess soil moisture variations to determine whether the foundation can continue to perform safely. Recognizing early warning signs and understanding soil-structure interaction helps identify when underpinning is not only necessary but urgent.

This section bridges the transition from how underpinning is performed to why it becomes essential, helping homeowners and builders make informed decisions about foundation stability.

When Does Foundation Movement Justify an Underpinning Solution?

Underpinning is required when a foundation shows measurable movement that threatens the building’s stability or functionality. Minor settling is natural in most structures, but progressive or uneven settlement indicates a deeper issue that the existing foundation cannot handle.

Situations that justify underpinning include:

- Significant wall or floor cracks, especially horizontal or stair-step cracks in masonry.

- Doors and windows that jam or misalign, showing uneven structural shifts.

- Visible foundation sinking or tilting, often detected by floor slope measurements.

- Gaps are forming between walls, ceilings, or skirting boards.

- Recurrent water infiltration or dampness caused by foundation displacement.

When movement exceeds acceptable engineering tolerances, underpinning becomes the only safe and permanent solution to re-establish equilibrium and prevent structural failure.

How Do Soil Shifts or Moisture Levels Lead to Underpinning Requirements?

Soil composition and moisture fluctuations directly influence the strength and stability of a building’s foundation. Expansive clay soils, loose fill, or areas with fluctuating groundwater can cause foundations to move or lose support.

Common soil-related causes include:

- Expansion and contraction of clay soils due to seasonal moisture changes.

- Erosion or washout from leaking pipes or poor drainage.

- Subsurface voids or sinkholes are forming under the footing.

- Differential moisture zones are created by nearby trees or landscaping.

- Vibration and ground disturbance from nearby construction or traffic.

By identifying these underlying causes through soil testing and geotechnical analysis, engineers can recommend underpinning solutions that stabilize the foundation and prevent future movement.

Should You Underpin a Foundation Showing Minor Cracks or Settlement?

Not all cracks require immediate underpinning. Minor, static cracks caused by natural settlement or plaster shrinkage are often harmless. However, persistent or widening cracks, especially those accompanied by water ingress or uneven flooring, may signal deeper structural issues.

Consider underpinning if:

- Cracks continue to grow despite cosmetic repairs.

- Floors slope noticeably over time.

- Foundation walls bow or bulge inward.

- There is evidence of water penetration or soil movement beneath the slab.

Before deciding, a qualified structural engineer should inspect the property to measure crack width, monitor movement patterns, and determine whether underpinning or another corrective method—such as drainage improvement or soil stabilization—is most appropriate.

By understanding how foundation movement, soil behaviour, and moisture variation interact, homeowners can make informed decisions about when underpinning is necessary to restore stability and protect long-term structural integrity.

Why Is Professional Oversight Crucial for Safe Underpinning?

Underpinning is one of the most technically demanding construction activities, and professional oversight is essential to ensure that every phase is executed safely, accurately, and in compliance with engineering standards. Because the process involves excavating beneath a live structure, even minor errors in design or sequencing can lead to serious structural damage.

Qualified professionals—structural engineers, geotechnical specialists, and licensed contractors—work together to oversee every stage, from soil evaluation and design approval to daily on-site monitoring. Their combined expertise guarantees that the underpinning is not only structurally sound but also completed without endangering the property or its occupants.

How Do Structural Engineers and Contractors Coordinate During Underpinning?

Successful underpinning depends on continuous coordination between engineers and contractors. Each party has defined responsibilities that align under a unified safety and quality framework.

Coordination process:

- Design phase: Structural engineers create drawings and load calculations, detailing excavation sequence, concrete specifications, and reinforcement design.

- Pre-construction meeting: Engineers brief contractors on safety protocols, monitoring systems, and contingency plans.

- Execution phase: Contractors follow the engineer’s step-by-step underpinning sequence while maintaining communication on site conditions or unexpected soil changes.

- Ongoing supervision: Engineers perform scheduled inspections to verify alignment, curing strength, and load transfer accuracy.

- Final verification: Both teams review test results and confirm that the underpinning meets all design and safety criteria before reloading the structure.

This close collaboration ensures that every decision—technical or operational—is reviewed, approved, and executed under expert supervision, reducing the chance of human or procedural error.

What Are the Risks of Proceeding Without Professional Supervision?

Attempting underpinning without professional oversight poses serious safety and financial risks. Because it involves altering the very structure that supports the building, unregulated work can result in catastrophic foundation failure or costly repairs.

Risks of unprofessional or unsupervised underpinning:

- Structural collapse or severe cracking due to improper excavation sequencing.

- Uneven load transfer, leading to long-term settlement or tilting.

- Violation of building codes, resulting in failed inspections or penalties.

- Water infiltration caused by neglected drainage or waterproofing details.

- Invalidated insurance or property resale issues due to a lack of certified documentation.

Without professional oversight, there is no assurance that the underpinning will meet structural, safety, or legal standards. Engaging qualified engineers and contractors ensures that every aspect of the project—from design to inspection—is carried out responsibly, providing lasting stability and full regulatory compliance.

Professional oversight transforms an underpinning from a high-risk structural task into a controlled, safe, and verifiable engineering process, safeguarding both the property and its occupants for years to come.

How Do Building Regulations Apply to an Underpinning Project?

Underpinning is classed as a structural alteration under UK building law, meaning it must comply with all relevant building regulations before, during, and after construction. These regulations safeguard the safety, stability, and durability of the structure while ensuring that all work is performed by competent professionals under approved engineering design.

Regulatory compliance extends from planning permission and permit acquisition to ongoing inspections by local authorities. Following these requirements ensures that the underpinning process remains fully legal, traceable, and verifiable—protecting both the property owner and future occupants.

Which UK Codes and Permits Are Required Before Underpinning Begins?

Before any underpinning work can start, the project must obtain formal approval from the local authority’s building control department. The application typically includes engineering drawings, calculations, and safety management plans prepared by a qualified structural engineer.

Key regulatory requirements include:

- Building Regulations Approval: Under the Building Regulations 2010 (as amended), underpinning falls under Part A – Structure, which governs structural stability.

- Party Wall Agreement: Required under the Party Wall etc. Act 1996 if the underpinning affects a shared or neighbouring wall.

- Planning Permission: Necessary only in special cases—such as listed buildings, conservation areas, or where basement expansion alters the property’s footprint.

- Health and Safety Compliance: Contractors must adhere to the Construction (Design and Management) Regulations 2015 (CDM 2015), which set duties for risk assessment, safe excavation, and worker protection.

- Insurance and Certification: Proof of professional indemnity insurance and an engineer certification for design sign-off.

Failure to secure these permissions can halt construction, lead to enforcement actions, or result in costly remedial work after completion.

How Do Inspections Ensure Compliance With Local Authority Standards?

Once work begins, building control inspectors from the local authority conduct staged inspections to verify that all underpinning activities meet approved plans and safety requirements. These inspections typically occur at critical milestones, including excavation, reinforcement, and concrete pouring.

Inspection responsibilities include:

- Checking excavation depth and alignment against engineering drawings.

- Verifying the use of correct reinforcement materials and concrete strength.

- Ensuring waterproofing and drainage installations meet Part C – Site preparation and resistance to contaminants and moisture.

- Confirming load transfer occurs only after full curing and structural sign-off by the engineer.

- Reviewing final reports and certifications before issuing a Completion Certificate.

Once the underpinning passes all inspections, the local authority issues official documentation confirming that the work complies with UK building regulations. This certification is essential for insurance coverage, resale, and future development approval.

By adhering to UK building regulations and cooperating with local inspections, underpinning projects maintain full legal integrity, guaranteeing structural safety, accountability, and peace of mind for property owners and engineers alike.

Why Should Underpinning Be Followed by Regular Maintenance Checks?

Completing the underpinning process doesn’t mark the end of structural care—it marks the beginning of a long-term maintenance cycle. Regular inspections and preventive maintenance ensure that the newly stabilized foundation continues to perform effectively under changing soil, moisture, and load conditions. These checks help identify early signs of movement, drainage issues, or moisture ingress before they escalate into costly repairs.

Ongoing maintenance also ensures that the underpinning investment remains protected, supporting long-term property safety, durability, and resale value.

What Maintenance Practices Sustain Foundation Stability After Underpinning?

Once the underpinning is complete, routine care is essential to preserve its structural performance. Proper maintenance helps prevent soil erosion, water damage, and settlement around the foundation perimeter.

Recommended maintenance practices include:

- Surface drainage management: Keep gutters, downpipes, and grading directed away from the foundation to prevent water pooling.

- Moisture control: Maintain consistent soil moisture levels near the foundation, especially in clay-heavy areas prone to expansion and shrinkage.

- Plumbing and waterproofing checks: Inspect sump pumps, drains, and waterproof membranes regularly for leaks or blockages.

- Ground movement monitoring: Keep an eye on minor cracks or floor changes and record any visible shifts over time.

- Tree and landscaping management: Avoid deep-rooted trees near the foundation that can absorb soil moisture unevenly.

These preventive steps preserve both the foundation’s integrity and the structural balance achieved through underpinning.

How Do Inspection Intervals Prevent Future Structural Deterioration?

Scheduled inspections provide measurable assurance that the underpinning continues to perform as designed. By tracking data and visible indicators over time, engineers and property owners can detect subtle changes that may signal emerging foundation stress.

Recommended inspection intervals:

- Initial follow-up: 3 to 6 months after completion, to confirm stabilization.

- Routine checks: Every 12 months thereafter, especially after extreme weather events.

- Professional assessments: Every 3 to 5 years, including level surveys or laser measurements.

Benefits of consistent inspections:

- Detect early signs of settlement, cracking, or water intrusion.

- Validate the performance of waterproofing and drainage systems.

- Ensure compliance with insurance or warranty requirements.

- Extend the lifespan of the underpinning system and the entire structure.

Through planned maintenance and inspection cycles, property owners can maintain the safety, strength, and long-term value of their underpinned foundation, ensuring it continues to perform reliably for decades.

What Common Mistakes Compromise the Effectiveness of Underpinning?

Even a well-designed underpinning project can fail if critical steps are rushed, skipped, or performed without proper engineering oversight. The effectiveness of underpinning depends on strict adherence to sequencing, curing, soil testing, and drainage management. Mistakes during these stages can lead to uneven settlement, cracking, or loss of structural support—undoing the very stability the process was meant to provide.

Understanding these common errors highlights why professional supervision, safety protocols, and inspection compliance are indispensable for a long-lasting result.

Why Does Premature Loading or Inadequate Curing Lead to Structural Failure?

One of the most frequent underpinning mistakes is applying load too soon or failing to allow the concrete adequate time to cure. The underpinning relies on concrete gaining full compressive strength before it can safely bear the structure’s weight. Rushing this process can cause immediate or delayed settlement, cracking, and even partial collapse.

Consequences of premature loading and poor curing:

- Reduced structural strength: The concrete may not reach its design strength if curing is incomplete.

- Uneven settlement: Unequal load transfer between new and old footings can distort the structure.

- Cracking and delamination: Moisture loss or early stress can cause the concrete to crack or separate from the existing foundation.

- Rework and safety hazards: Corrective underpinning is costly, time-consuming, and risk-prone.

To prevent these issues, engineers monitor curing periods closely and verify strength with compression testing before any load transfer occurs.

How Does Ignoring Soil Data or Water Control Impact the Results?

Neglecting soil analysis or failing to manage groundwater is another critical cause of underpinning failure. The soil beneath a structure dictates how well the new foundation will perform; without accurate data, even the strongest concrete base may lose stability over time.

Risks of poor soil and water management:

- Inadequate bearing capacity: If soil strength is overestimated, the foundation may settle unevenly.

- Erosion and washout: Poor drainage allows water to erode or soften the soil, undermining the new footing.

- Hydrostatic pressure: Uncontrolled groundwater increases lateral force on basement walls, causing cracks or bowing.

- Frost heave or shrink-swell: Ignoring soil moisture variations can lead to seasonal expansion and contraction beneath the foundation.

Proper soil testing, groundwater monitoring, and integrated waterproofing ensure that the underpinning performs reliably under varying environmental conditions.

By avoiding premature loading, ensuring full curing, and basing every decision on accurate soil and drainage data, underpinning projects maintain the strength, alignment, and durability required for long-term foundation stability.