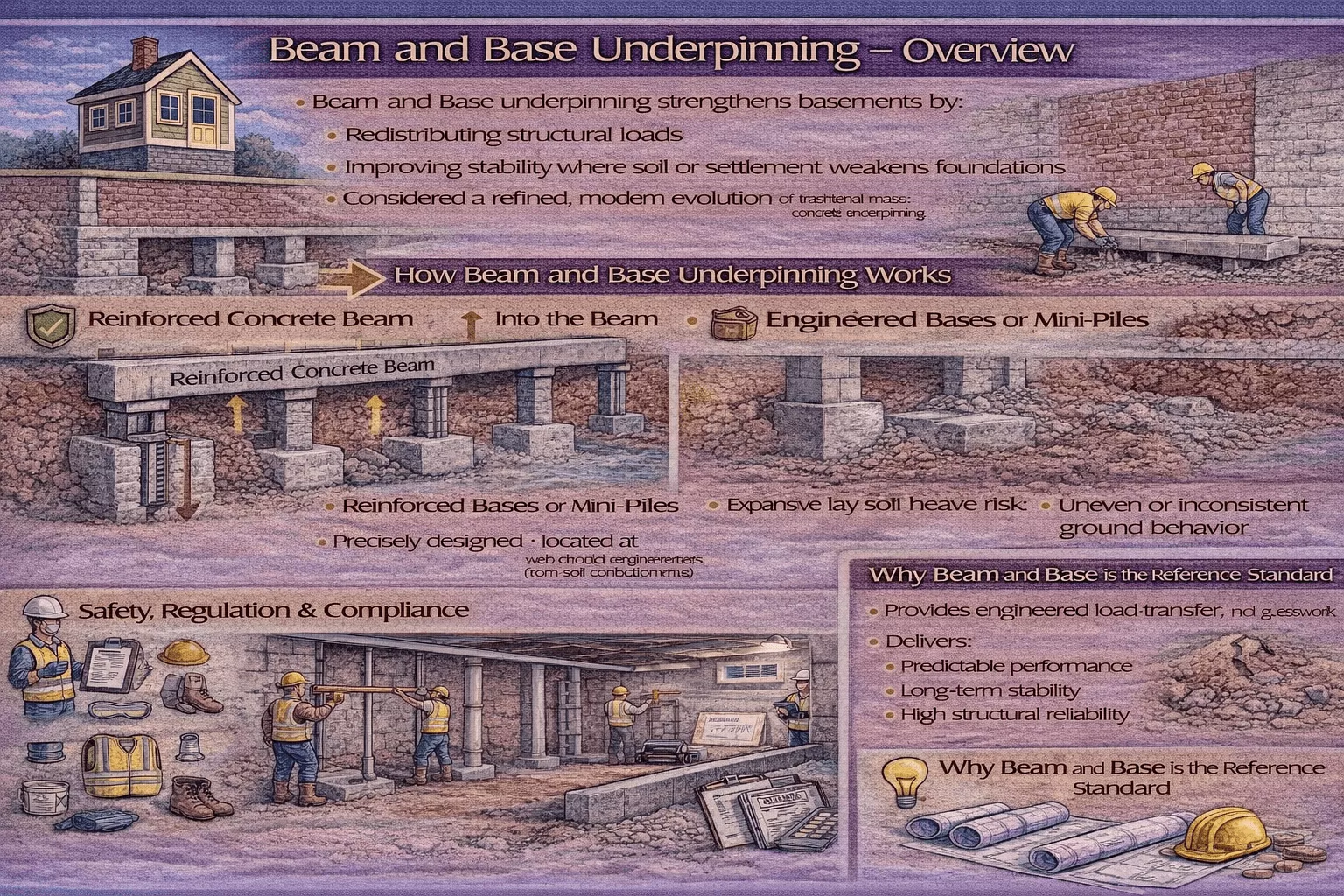

Beam and Base underpinning strengthens a basement by redistributing structural loads through a reinforced concrete beam and engineered bases, improving stability where soil conditions, settlement, or heavy applied loads weaken the existing foundation. This method refines traditional mass concrete underpinning with greater precision, transferring the building’s weight to designed support points or mini-piles and adapting to shallow footings, clay expansion risks, and variable ground behaviour. The process enhances basement conversions by increasing usable space, improving structural integrity, and supporting key requirements such as moisture control, code compliance, and safe ventilation planning.

Safety and compliance drive every stage of the work under OSHA, requiring proper excavation, engineered shoring, PPE use, and final municipal inspection to secure long-term foundation performance. Beam and Base remains the reference standard for underpinning because it provides engineered load transfer and reliable structural support, while alternative systems, mini-piles, resin injection, and soil modification are chosen only where deep foundations, loose soils, or severe ground variability demand specialized solutions.

How Does Beam and Base Strengthen a Basement?

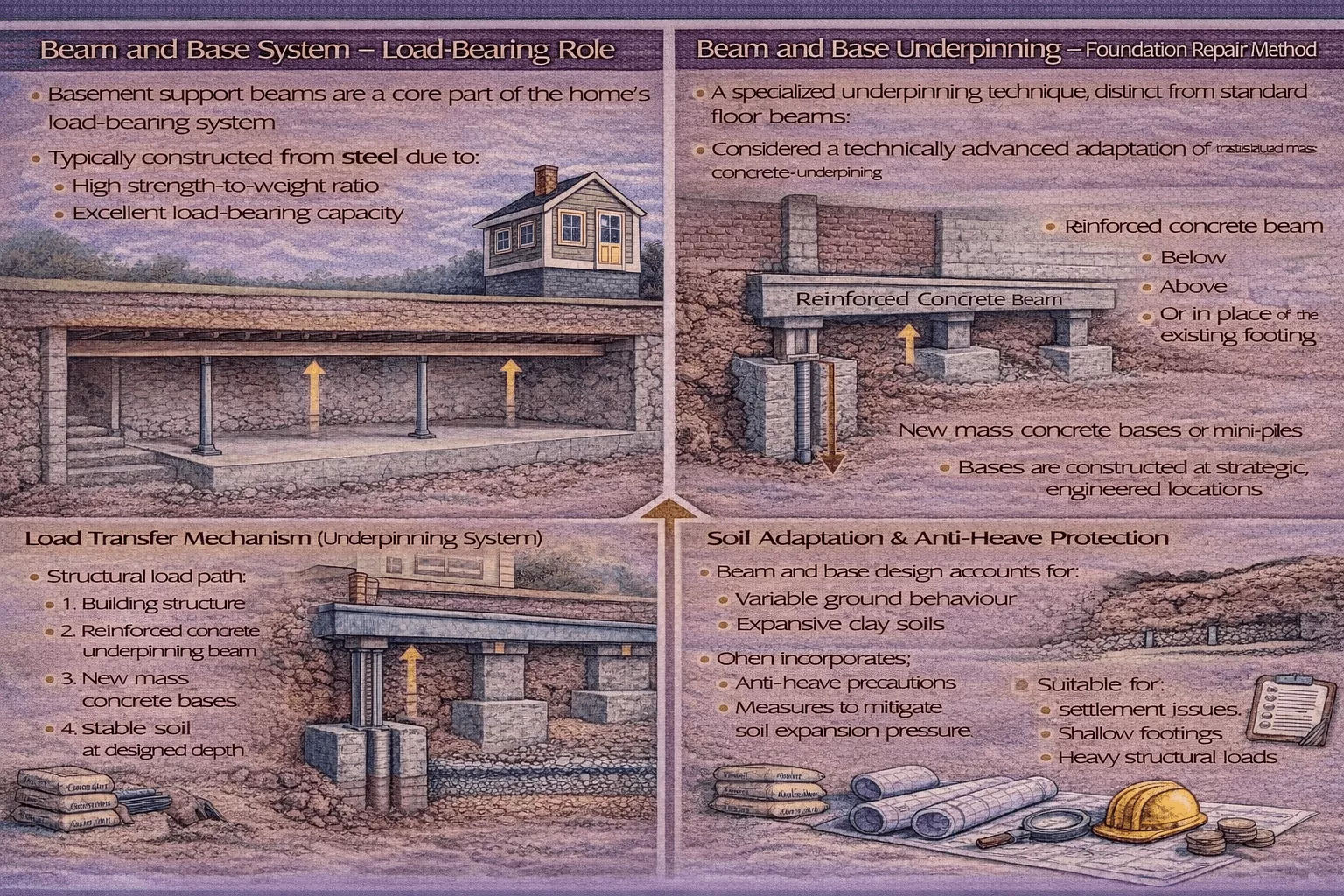

The beam and base system strengthens a basement by acting as a crucial component of the structure’s load-bearing system, distributing the entire weight of the structure to the foundation. Standard basement support beams, often utilizing steel for its high strength-to-weight ratio and excellent load-bearing capacity, are integral parts of the flooring system. They typically run down the centre of the home, distributing the weight of the entire structure via floor joists attached to them, transferring the heavy loads from upper floors through vertical support posts down to the foundation.

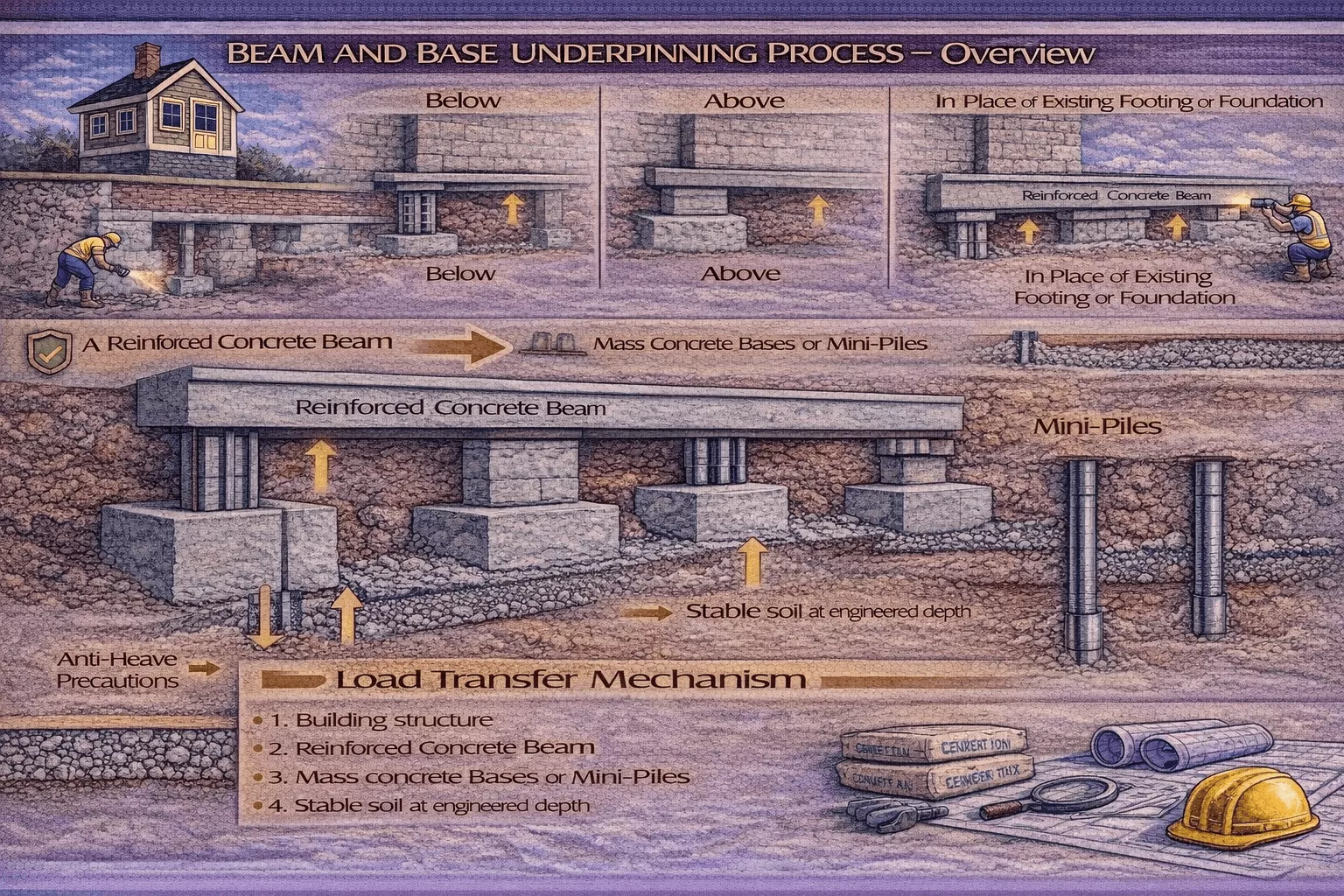

When referring to the specialized foundation repair technique, the beam and base method of underpinning is a technically advanced adaptation of traditional mass concrete underpinning. This method strengthens the structure by constructing a reinforced concrete beam below, above, or in place of the existing footing. This beam then transfers the load of the building to new mass concrete bases constructed at the designed strategic locations. The beam design and the required base sizes and depths are dependent upon the configuration of the building, the applied loads, and the prevailing ground conditions, often incorporating anti-heave precautions to mitigate potential expansion of clay soils.

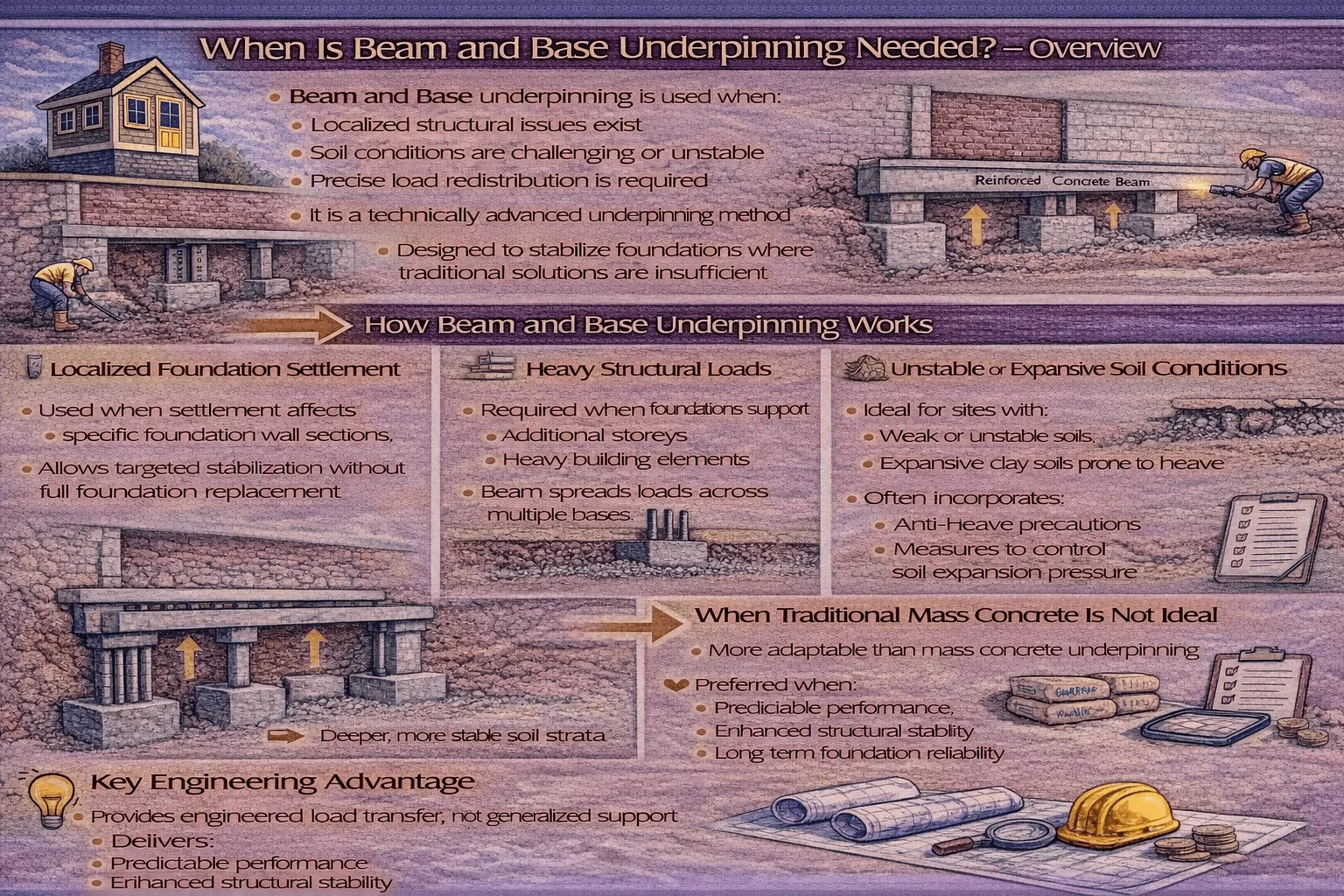

When Is Beam and Base Underpinning Needed?

Beam and Base underpinning is needed when localized structural issues or challenging soil conditions require a technically advanced method to stabilize the foundation and manage load distribution. This method involves constructing a reinforced concrete beam beneath, above, or in replacement of the existing footing, which transfers the building’s load to strategically placed concrete bases or mini-piles.

This technique is typically employed under the following circumstances:

- To address localized settlement affecting the existing foundation wall.

- To strengthen foundations supporting heavy applied loads, ensuring the load is adequately transferred across a broader area.

- When existing ground conditions, such as prevailing unstable soil or the potential expansion of clay soils, necessitate transferring the building’s weight down to stable soil strata, often incorporates anti-heave precautions.

- As a more adaptable solution than traditional mass concrete underpinning, where the beam design and base locations must be precisely engineered based on the building’s configuration, applied loads, and specific ground conditions.

How Does the Beam and Base Underpinning Process Run?

The beam and base underpinning process runs as a technically advanced adaptation of traditional mass concrete underpinning. The method involves constructing a reinforced concrete beam either below, above, or in place of the existing footing or foundation. This beam transfers the building’s weight and applied load across a broader area to strategically designed mass concrete bases or, alternatively, to stable soil via mini-piles. This process is ideal for structures with shallow foundations and is highly adaptable to various structural and soil conditions.

The beam design and the size and depth of the bases are determined by the configuration of the building, the applied loads, and the prevailing ground conditions. Mini-piles are typically utilized when ground conditions are very variable, access is restrictive, environmental pollution aspects are significant, or where structural movements must be minimal. Anti-heave precautions are also often incorporated when potential expansion of clay soils may occur.

How Does Beam and Base Enhance Basement Conversion?

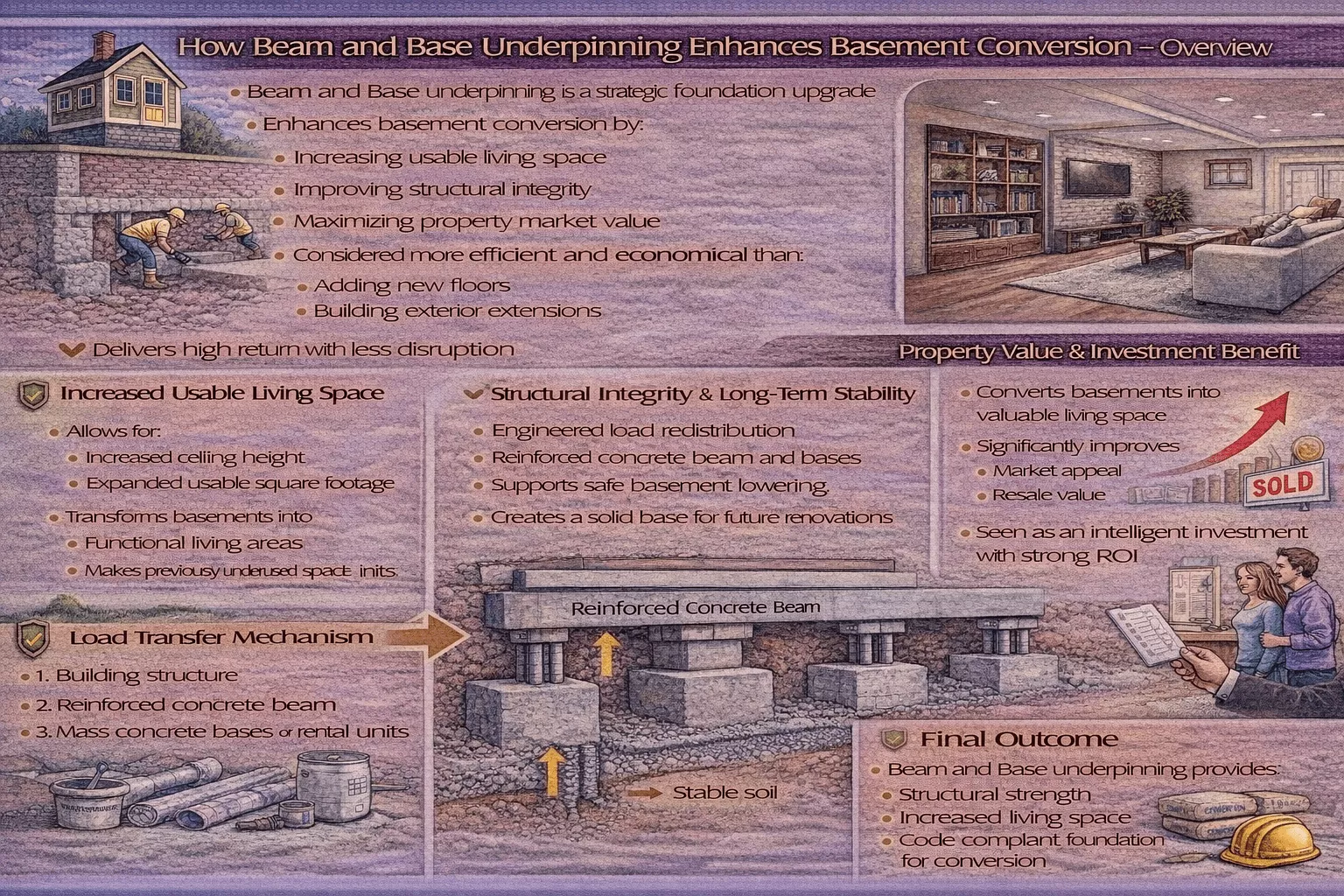

The Beam and Base approach, often synonymous with foundational underpinning, enhances basement conversion primarily by increasing usable living space, improving structural integrity, and maximizing the property’s market value. This strategic foundational work is considered a more efficient and economical solution compared to highly disruptive construction alternatives like adding new floors or building extensions. By strategically increasing the ceiling height and overall usable square footage, Beam and Base transform the basement into a functional living space, making it an intelligent investment that significantly enhances the home’s market value.

While the structural foundation is critical, the enhancement of the overall conversion also requires addressing essential factors for safety and long-term success. These preparatory steps include assessing key elements such as prioritizing moisture control through waterproofing the space, reviewing local building codes to ensure legal compliance and proper permitting, and planning effective lighting and ventilation. Addressing these elements early builds upon the foundational enhancement, resulting in a solid, code-compliant, and inviting basement transformation.

What Rules and Safety Steps Apply to Beam and Base Work?

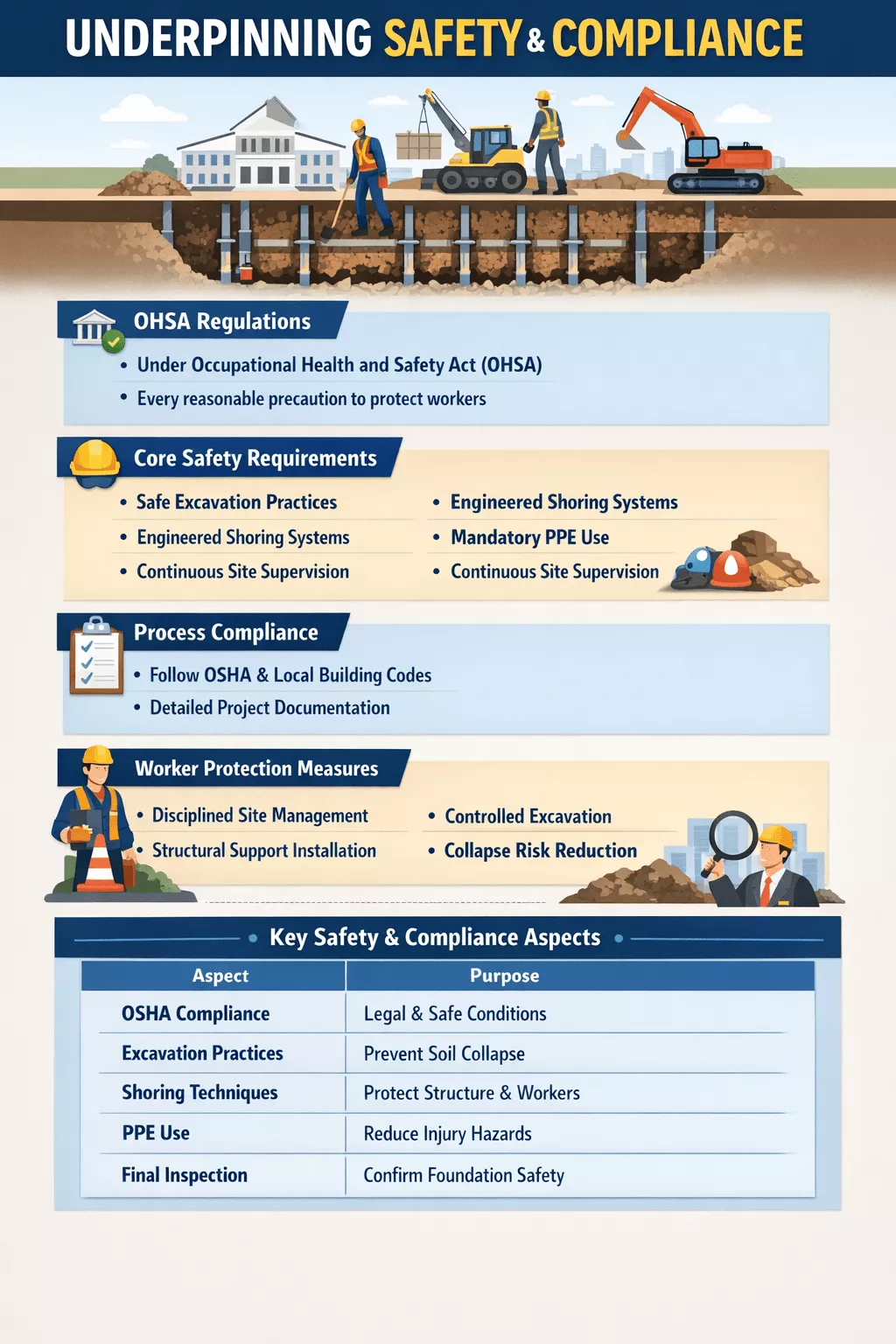

Beam and base underpinning work falls under the Occupational Health and Safety Act (OHSA), which requires employers to take every reasonable precaution to protect workers from hazards associated with excavation, shoring, and structural support activities. Compliance depends on strict adherence to safe excavation practices, proper shoring, mandatory use of PPE, and continuous oversight to ensure site stability. Each stage of the underpinning process must meet OSHA requirements and local building codes, with a final municipal inspection required to confirm that the new foundation is structurally secure before approval.

Worker protection and project safety rely on disciplined site management, controlled excavation, correct structural support procedures, and thorough documentation. These steps minimize risk, prevent collapse during underpinning operations, and ensure that the completed foundation meets regulatory standards for long-term safety and performance.

Key Safety and Compliance Aspects:

| Aspect | Requirement | Purpose |

|---|---|---|

| OSHA Compliance | Follow all act provisions throughout the project | Ensures legal and safe working conditions |

| Excavation Practices | Maintain proper excavation depth and stability | Prevents soil collapse and structural failure |

| Shoring Techniques | Use engineered shoring where required | Protects workers and supports the existing structure |

| PPE Use | Mandatory protective equipment for all workers | Reduces injury risk from on-site hazards |

| Final Inspection | City inspector verifies code compliance | Confirms foundation safety before approval |

Why Are Other Underpinning Options Measured Against the Beam and Base?

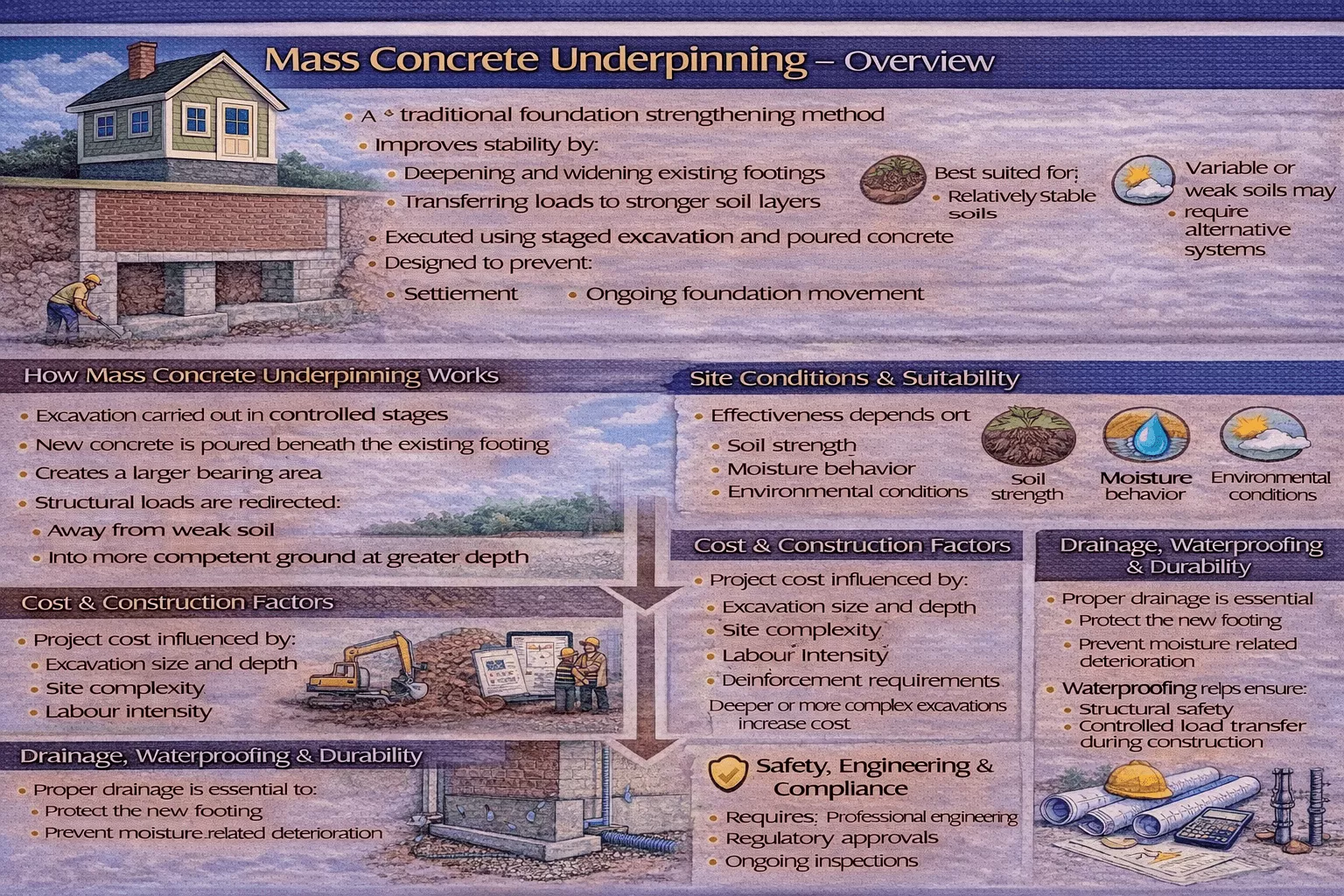

Other underpinning options are measured against the Beam and Base method because it represents a crucial, technically advanced evolution of the simplest and original technique, mass concrete underpinning. While mass concrete underpinning involves directly pouring concrete into excavations beneath the existing foundation, the Beam and Base method refines this by constructing a reinforced concrete beam, either below, above, or replacing the existing footing, to strategically redistribute the building’s weight to designed mass concrete bases. This structured, reliable approach makes Beam and Base a common and structurally significant standard. Specialized methods, such as mini-piled underpinning, are typically reserved for challenging scenarios like highly variable ground conditions, deep foundations (2 to 15 metres), or severely restrictive access, positioning Beam and Base as the conventional reference point for standard underpinning requirements.

How Do Mini-Piles Compare With Beam and Base in Deep Ground?

Mini-piles provide a modern deep-foundation solution that outperforms traditional beam and base systems in challenging ground conditions. Their high-strength, small-diameter steel casings or threaded bars anchor deeply into stable soil layers, gaining capacity through end bearing and skin friction. This allows mini-piles to resist heavy vertical loads and significant tension forces, making them ideal where deep anchoring and long-term stability are required. Their compact installation equipment also makes them suitable for restricted-access sites where conventional underpinning is impractical.

Mini-piled underpinning offers faster installation, minimal disruption, and immediate load-bearing capability, making it effective in varied soils and environments where beam and base or mass concrete underpinning may underperform. By drilling, reinforcing, and concretizing deep narrow piles, this method delivers a robust structural solution with high adaptability and superior performance in deep or unstable ground.

Key Differences Between Mini-Piles and Beam & Base:

| Aspect | Mini-Piles | Beam & Base |

|---|---|---|

| Load Capacity | High vertical & tension load capacity | High vertical load redistribution |

| Depth Suitability | Ideal for deep, unstable, or variable soils | Better for shallow to moderate depths |

| Installation Access | Excellent for confined or restricted areas | Requires more working space |

| Equipment Needed | Small drilling rigs, minimal equipment | Larger excavation tools are required |

| Speed of Use | Can take immediate loads | Requires curing time |

| Soil Compatibility | Performs well in most soil types | Less effective in highly variable soils |

| Structural Role | Acts as deep foundation support | Reinforces and redistributes via beams and bases |

How Does Resin Injection Compare With Beam and Base in Loose Soil?

The comparison between resin injection and structural methods like beam and base or underpinning in loose soil highlights fundamentally different approaches to stabilization. Resin injection involves strengthening the ground beneath the footing by using a geopolymer injection process to improve the problematic soil in situ, effectively acting like keyhole surgery for the ground rather than bypassing it.

In contrast, methods like traditional underpinning or using helical piers (which are similar to beam and base solutions) are designed to bypass the loose soil.

These structural methods provide stability by:

- Extending the footing to a deeper, more stable layer of soil, or

- Transferring the weight of the structure to load-bearing soil or bedrock, provides stability suitable for challenging soil conditions.

How Does Soil Replacement Compare With Beam and Base for Load Support?

A comparison of soil replacement and modification techniques with beam and base methods for load support reveals that both are highly effective foundation solutions tailored to specific structural needs, site access limitations, and soil conditions. Beam and base methods, which encompass systems like poured concrete underpinning and steel beam underpinning, are common methods for reinforcing existing home foundations, chosen primarily to distribute structural loads based on site access and the specific structural needs of the building.

Conversely, traditional soil replacement involves massive over-excavation and is used to provide support for settlement-sensitive structures in very difficult soil conditions, such as clay, silt, or organic soils. However, innovative soil modification systems have been developed to achieve similar or greater capacity without the extensive process of full replacement.

The precision Rammed Aggregate Pier (RAP) System, known as Geopier, is a ground improvement technique developed to avoid massive over-excavation and replacement.

This innovative method compares favourably to traditional soil replacement because it:

- Provides an efficient and cost-effective foundation solution for difficult soil conditions.

- Offers greater load capacity than traditional stone columns, particularly in non-sand soil conditions.

- Avoids the necessity of massive over-excavation in cohesive soils.