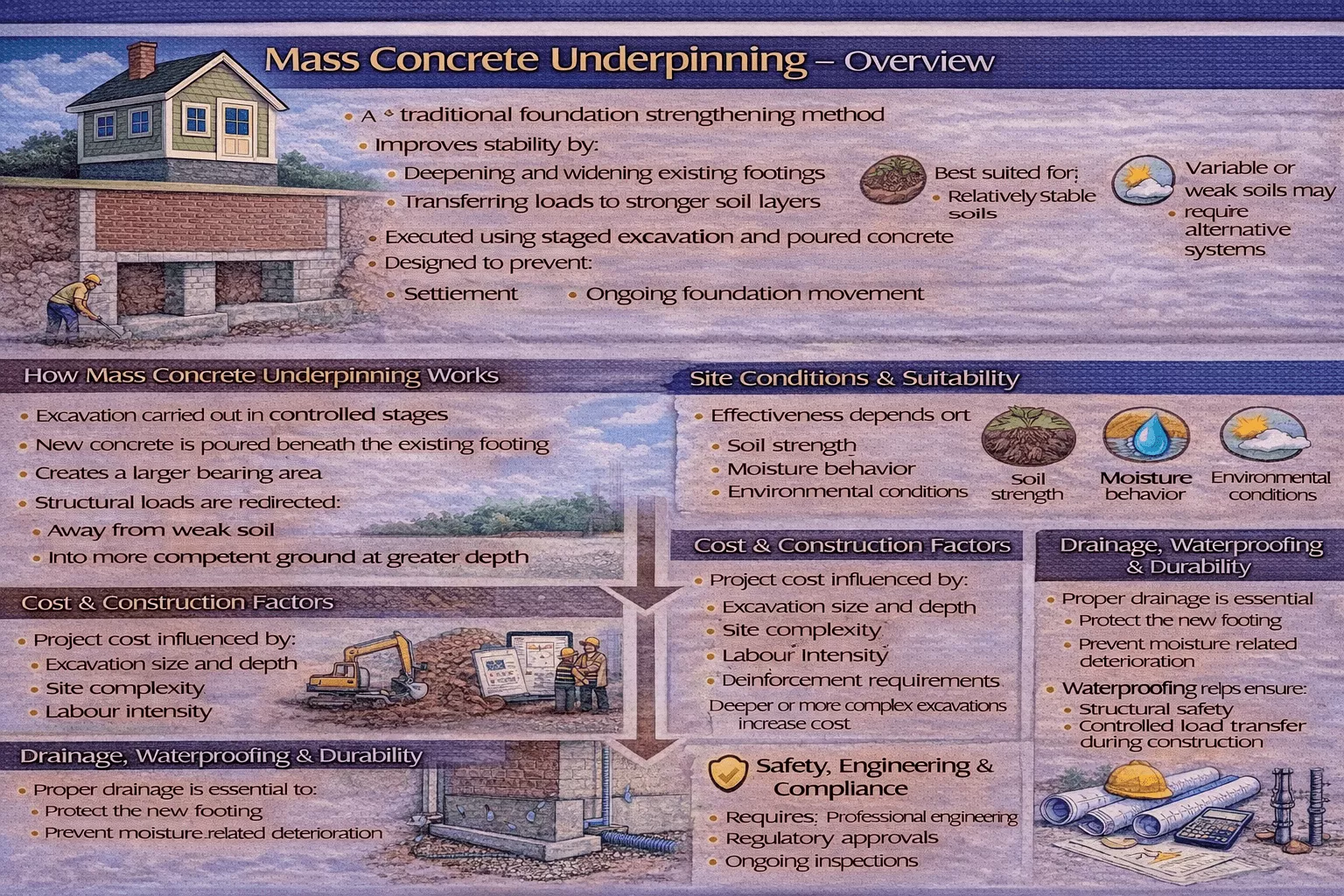

Mass-concrete underpinning strengthens existing foundations by deepening and widening the footing through staged excavation and poured concrete. The method improves stability by transferring structural loads to stronger soil layers and preventing settlement. Site conditions guide suitability because soil strength, moisture behaviour, and environmental factors determine how effectively the new footing supports the structure.

Project cost depends on excavation size, depth, complexity, labour demands, and reinforcement needs. Effective results require proper drainage and waterproofing to protect the upgraded foundation from moisture. Regulatory compliance, engineering design, and inspection control safety throughout the process. Alternative systems such as beam-and-base, mini-piles, and helical piles address sites with higher loads or variable soil conditions.

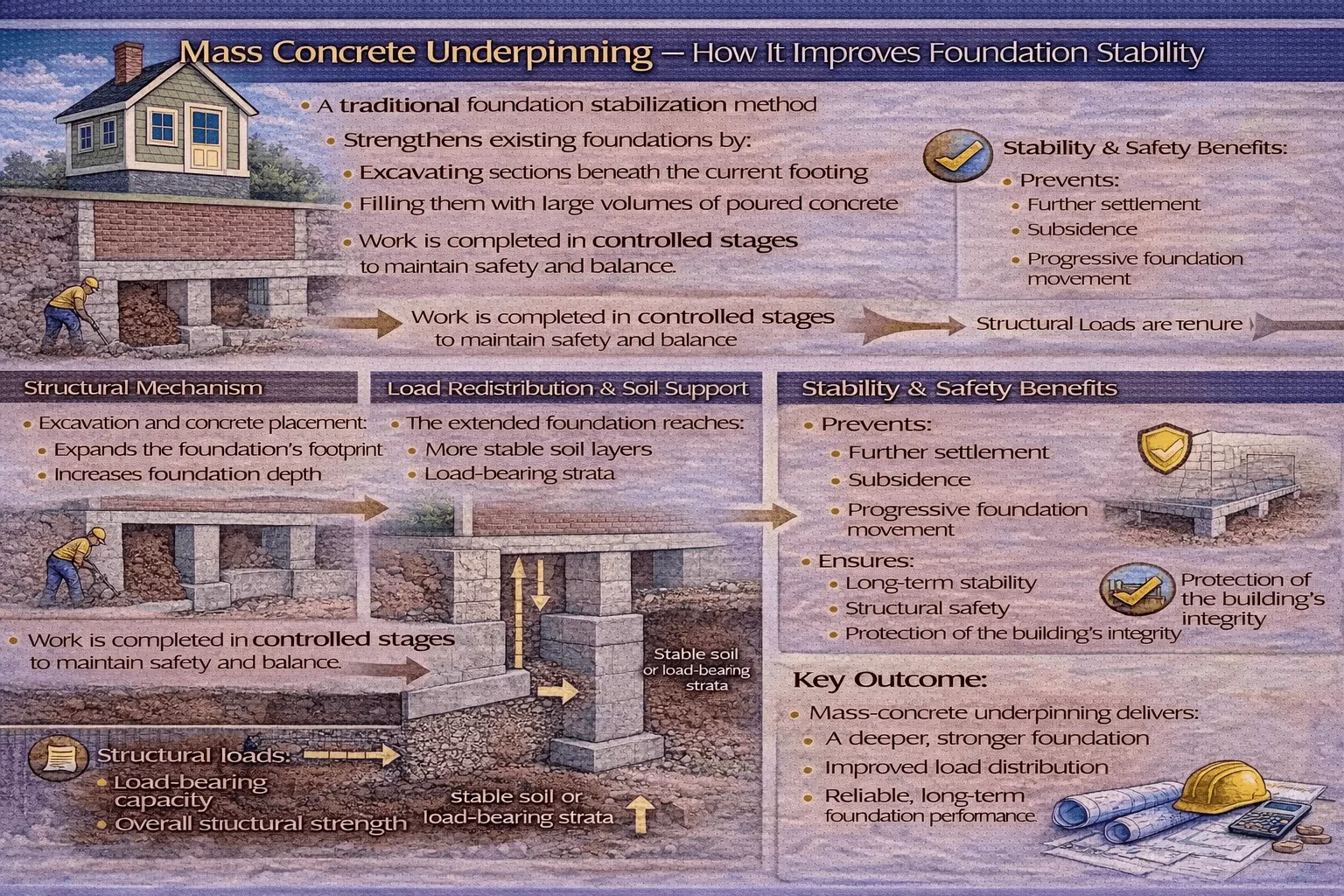

How does mass-concrete underpinning improve foundation stability?

Mass-concrete underpinning improves foundation stability by strengthening and stabilizing the foundation of an existing structure through a traditional method. It involves excavating sections beneath the existing foundation and filling them with large volumes of poured concrete. This process expands the foundation’s footprint and depth, which significantly increases its load-bearing capacity.

By extending the foundation to more stable soil layers or load-bearing strata, the technique effectively redistributes the structural loads, preventing further settlement or subsidence and ultimately ensuring the stability and safety of the building.

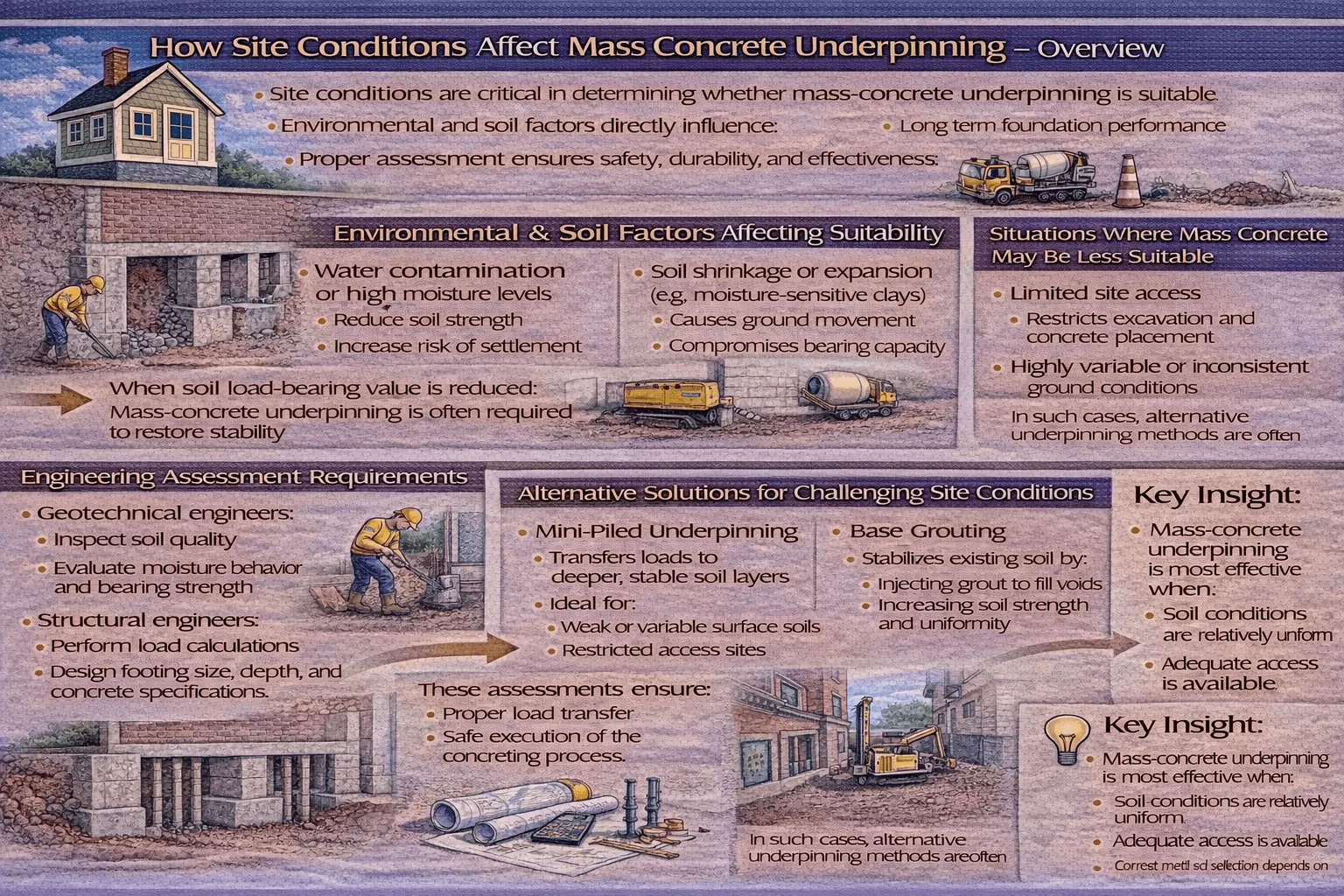

Why do site conditions affect mass-concrete underpinning suitability?

Site conditions affect mass-concrete underpinning suitability primarily because environmental factors, such as water contamination and the sudden shrinkage or expansion of soil, can significantly reduce the soil’s load-bearing value. When the soil’s load-bearing value is compromised, mass concrete underpinning is often employed as a necessary solution, requiring geotechnical engineers to inspect the soil quality and structural engineers to perform the necessary calculations for the concreting process.

Conversely, mass concrete may be less suitable for areas with limited access or highly variable ground conditions, where alternative techniques, such as mini-piled underpinning (which reaches a deeper, stable layer) or base grouting (which stabilizes and strengthens existing soil by filling voids), are often ideal for preventing differential settlement.

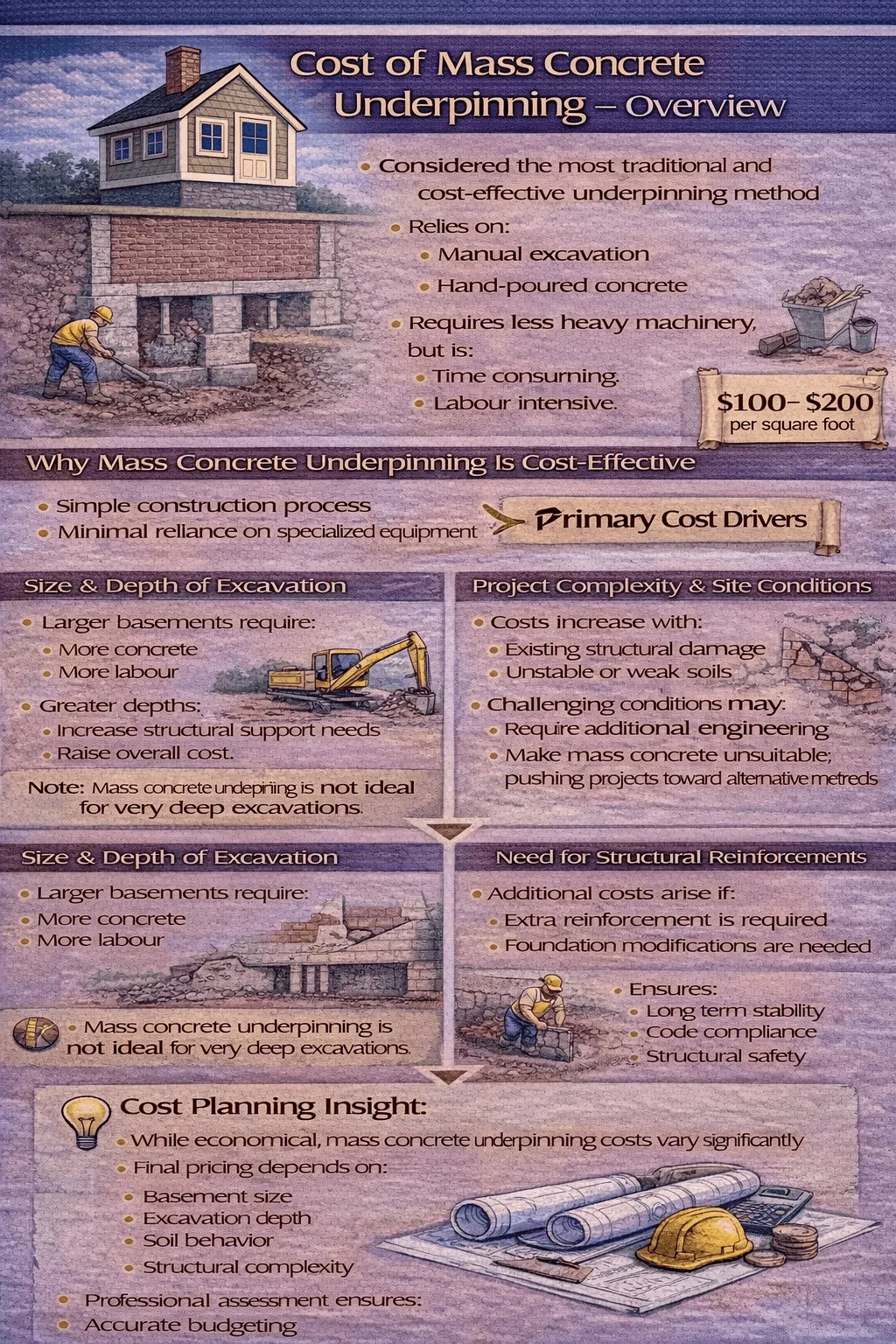

What drives the total cost of mass-concrete underpinning?

The total cost of mass-concrete underpinning is driven by several project-specific and structural factors, even though it is generally considered the most cost-effective and traditional foundation underpinning method available. While mass concrete relies on digging holes and filling them by hand, minimizing the need for heavy excavation equipment, the process remains time-consuming and labour-intensive. Overall, underpinning projects typically fall within an average cost range of $100 to $200 per square foot.

The primary cost drivers for mass concrete underpinning projects include the following considerations:

- Size and Depth of Excavation: Larger basements require more materials and labour, increasing the overall cost. Greater depths demand more extensive structural support, and it is important to note that mass concrete underpinning is generally unsuitable for very deep excavations.

- Project Complexity and Site Conditions: Difficult or challenging conditions, such as existing structural issues or the presence of unstable soils, can drive up expenses and may make the mass concrete method inappropriate.

- Labour Intensity: Despite being ideal for areas with limited access to heavy machinery, the process is inherently labour-intensive and time-consuming, meaning labour costs contribute significantly to the final price.

- Need for Structural Reinforcements: The cost increases if additional modifications or extra structural reinforcements are necessary to ensure the long-term stability of the foundation.

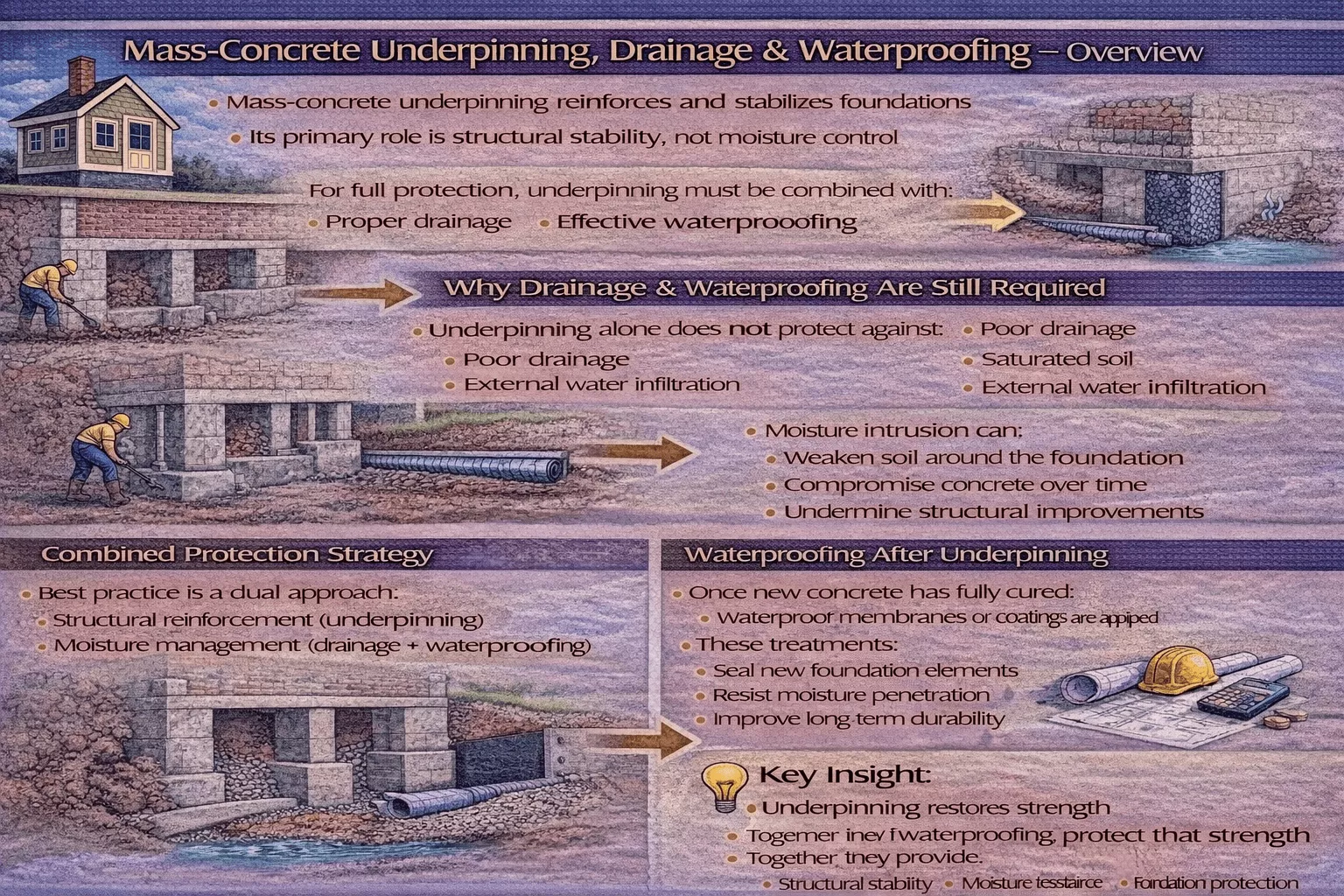

How does mass-concrete underpinning link with drainage and waterproofing?

The link between mass-concrete underpinning and drainage and waterproofing is that underpinning reinforces the foundation, but requires supplementary moisture control for complete protection. Mass concrete underpinning, including its technically advanced beam and base adaptations used to transfer building loads to strategic bases, focuses primarily on restoring structural stability and reinforcing the foundation. However, underpinning reinforcement alone does not shield the structure against external threats such as poor drainage, saturated soil, or water infiltration.

Since moisture intrusion can compromise the integrity of the foundation even after it has been strengthened, a combined approach, underpinning alongside proper drainage and waterproofing, is essential for comprehensive protection. Specifically, applying waterproofing treatments or protective coatings to the new foundation elements once the concrete has cured helps enhance durability and resist moisture penetration.

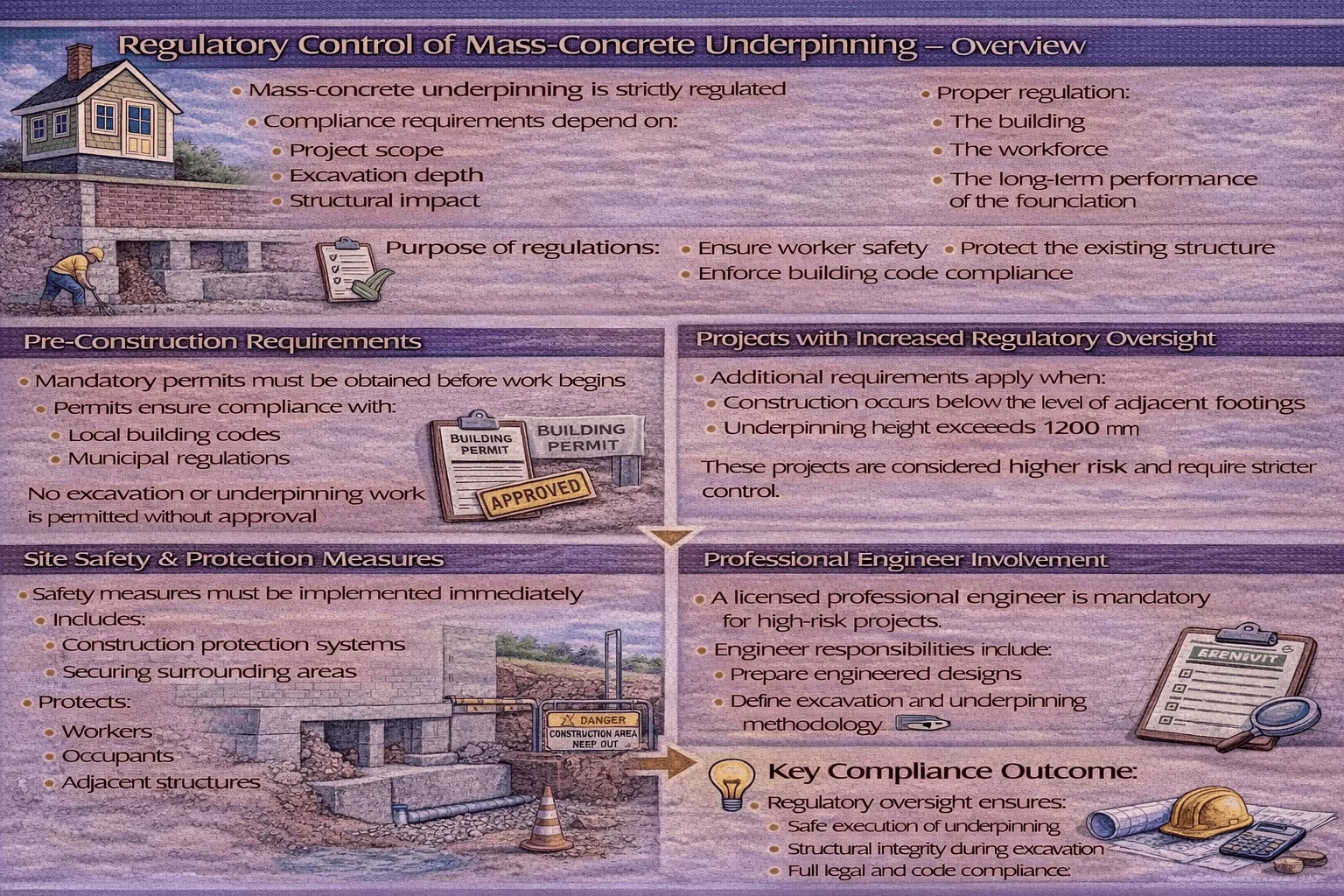

How do regulations control mass-concrete underpinning work?

Regulations control mass-concrete underpinning work through mandatory compliance and specific oversight requirements dictated by the project scope. Before work begins, it is critical to obtain all necessary permits to ensure compliance with local building codes and regulations. Furthermore, necessary safety measures, including construction protection and securing the surrounding area, must be implemented immediately to protect both workers and the structure. For projects involving construction below the level of adjacent footings or those that exceed 1200 mm in height, the regulatory requirements intensify, mandating a professional engineer’s design and continuous field review.

This professional oversight requires providing mandatory testing and submitting reports during the first and last stages of construction.

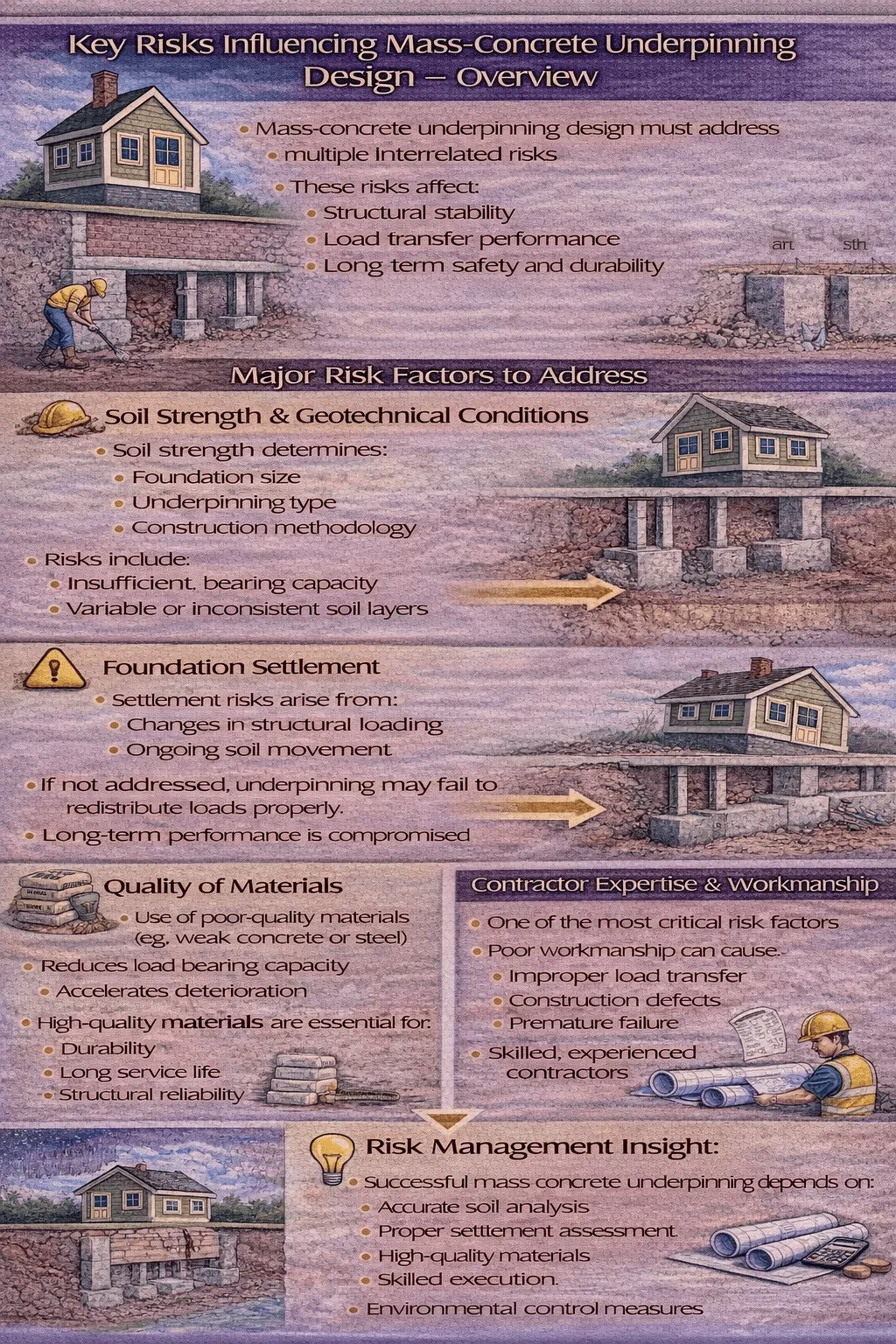

Which risks influence mass-concrete underpinning design?

The risks influencing mass-concrete underpinning design are multifaceted and primarily relate to site conditions, material quality, and execution expertise.

These critical risks must be addressed during the design and execution phases to ensure enhanced support, stability, and safety:

- Soil Strength and Geotechnical Conditions: Soil strength is a crucial determinant that dictates the necessary foundation size, type, and overall construction methodology. Insufficient or variable soil strength requires appropriate support systems during excavation to prevent walls from collapsing.

- Foundation Settlement: Changes in the structural load or underlying soil shifts can negatively affect the underpinning’s performance. Unaddressed settlement issues can prevent the system from effectively redistributing structural loads and ensuring longevity.

- Quality of Materials: Using inferior materials, such as low-quality concrete or steel, compromises the stability and durability of the underpinning, leading to rapid deterioration and structural weakness.

- Expertise of Contractors and Workmanship: Poor installation or a lack of skilled and experienced contractors is a significant risk factor. Poor workmanship can lead directly to structural issues, reducing the effective lifespan and performance of the underpinning system over time.

- Environmental Conditions: External factors like high groundwater levels and adverse weather conditions can impact the underpinning’s integrity, requiring regular maintenance and inspection to ensure long-term stability.

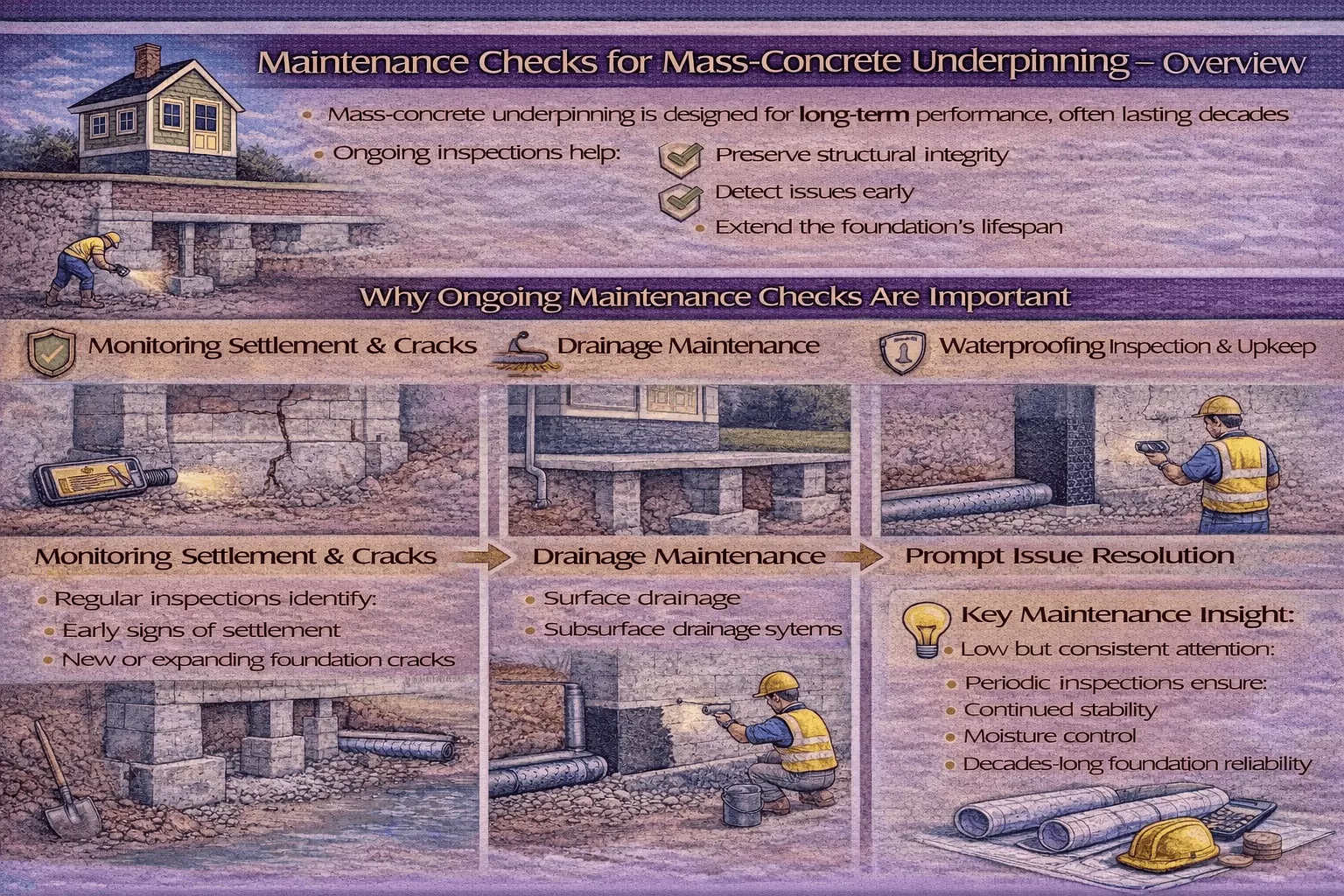

Why does mass-concrete underpinning require ongoing maintenance checks?

Mass-concrete underpinning requires ongoing maintenance checks primarily to ensure the long-term stability and structural integrity of the foundation, despite being designed to provide long-lasting support for many decades. While maintenance needs are generally minimal, periodic inspections are crucial to address potential issues promptly, prevent further damage, and prolong the foundation’s lifespan.

The reasons these checks are essential include:

- Monitoring for any early signs of settlement or cracks in the foundation to catch potential issues before they worsen.

- Maintaining proper drainage around the structure helps prevent soil erosion and subsequent settlement issues.

- Checking and maintaining waterproofing measures, such as sealants, drainage systems, or moisture barriers, to prevent future water damage.

- Addressing any potential issues promptly to ensure the foundation remains stable and to prevent further structural damage.

How does mass-concrete underpinning compare with other underpinning systems?

Mass-concrete underpinning is a traditional foundation repair technique that compares to other underpinning systems based on complexity, versatility, and suitability for various ground conditions. The traditional mass concrete method involves excavating small, rectangular pits in a staggered sequence beneath the existing foundation and pouring concrete to form new footings that extend to a stable soil layer, making it suitable mainly for shallow foundations and relatively stable soil conditions.

Other systems offer technically advanced solutions for more complex or challenging requirements:

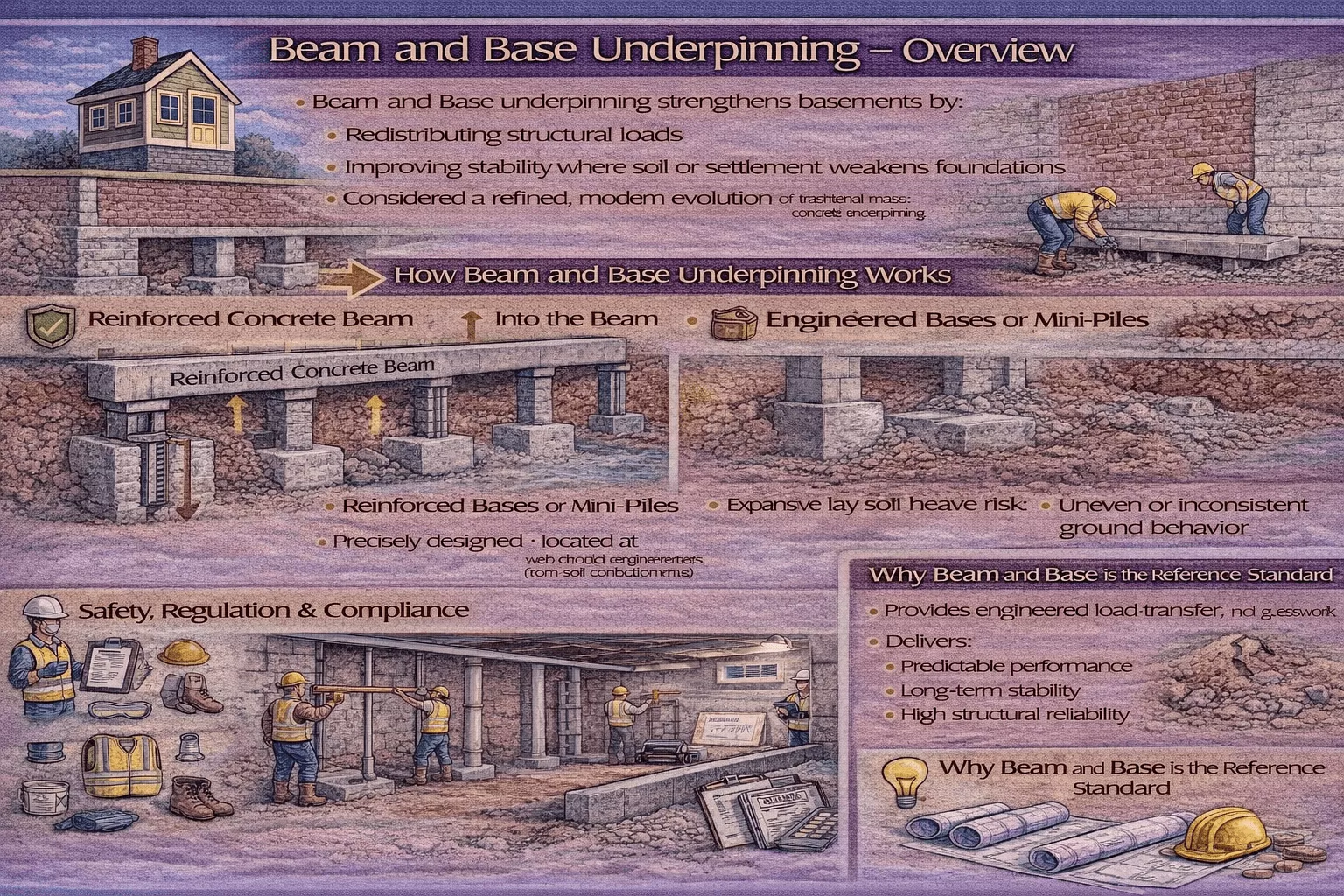

- Beam and Base Method: This is a technically advanced adaptation of mass concrete underpinning. It involves constructing a reinforced concrete beam (below, above, or replacing the existing footing) to transfer the load of the building to strategically designed mass concrete bases. This method allows for customized design based on applied loads and prevailing ground conditions, often incorporating anti-heave precautions for potential expansion in clay soils.

- Mini-Piles: Mini-piles have the greatest use where ground conditions are highly variable, access is restrictive, environmental pollution aspects are significant, and where structural movements in service must be kept minimal, offering greater stability and versatility than traditional concrete approaches.

- Helical Piles: These pile systems are often considered a better choice compared to concrete solutions for addressing foundation issues promptly and maintaining the overall integrity of the structure.

Why is mass-concrete underpinning compared with beam-and-base systems?

Mass-concrete underpinning stabilizes shallow foundations by excavating small, sequenced pits beneath the existing footing and filling them with poured concrete. This creates deeper, wider footings that rest on stronger soil and redistribute structural loads. The method suits stable soils, low excavation depths, and sites where access is limited.

Beam-and-base underpinning modifies this approach by adding a reinforced concrete beam below, above, or in place of the original footing. The beam transfers structural loads to mass-concrete bases positioned at strategic depths based on soil behaviour. This configuration provides engineered control over load paths and supports higher or uneven structural loads.

The two methods are compared because both strengthen foundations but serve different engineering needs. Mass-concrete underpinning fits traditional, shallow-depth projects, whereas beam-and-base systems suit sites with more complex soil profiles, heavier loads, or structural irregularities. Selection depends on load characteristics, access constraints, and ground conditions.

Mass-Concrete vs Beam-and-Base Underpinning Comparison:

| Feature | Mass-Concrete Underpinning | Beam-and-Base Underpinning |

|---|---|---|

| Core Method | Sequenced pits filled with concrete beneath the existing footing | Reinforced concrete beam transfers loads to discrete concrete bases |

| Load Distribution | Uniform load spread through large concrete blocks | Engineered load transfer through a designed beam system |

| Best For | Shallow foundations, stable soils, limited access | Heavy loads, uneven load paths, deeper or variable soil conditions |

| Structural Control | Traditional, low-complexity approach | High structural control with reinforced design |

| Soil Suitability | Stable, predictable soils | Sites with variable or challenging soil behaviour |

| Equipment Access | Ideal for constrained or internal spaces | Requires more working room for beam construction |

| Engineering Complexity | Lower | Higher due to beam design and load calculations |

| Typical Use Cases | Residential homes, small structures | Large buildings, heavy foundations, complex sites |

How do project risks guide underpinning method selection?

The project risks guide underpinning method selection by defining the necessary risk treatment and prioritization strategy required to meet project goals. Risks are analyzed based on their potential to derail the project or impact the overall schedule and budget. High-priority risks, such as those related to the foundation itself, for example, poor or unstable soil conditions, mandate immediate and extensive reinforcement measures, as the quality of the soil plays a crucial role in the foundation’s strength requirements.

Therefore, the chosen underpinning method is essentially a customized risk treatment strategy (like risk reduction or avoidance) that is refined to fit the specific risks identified, ensuring the plan aligns with the project’s established risk appetite and goals.

Why do some projects use other underpinning methods instead of mass concrete?

The reason some projects use other underpinning methods instead of mass concrete is that the technique is often very slow and labour-intensive, which makes alternative, more efficient methods preferable for typical construction schedules.

While mass concrete’s biggest advantage is that it involves no heavy machinery, making it suitable for situations where access is difficult, the overall choice of method depends on many factors related to the building’s needs and the specific soil conditions, such as:

- The necessity of accommodating potential soil sinking over time.

- Future requirements, including whether the building needs to be expanded or reconstructed.

How do soil replacement and resin injection differ in load transfer?

Soil replacement and resin injection differ in load transfer primarily based on how they treat the existing ground. Soil replacement typically involves bypassing the problem soil entirely, removing weak material and replacing it with a stable material through which the load is transferred. Conversely, resin injection, often using a process called geopolymer injection (described as keyhole surgery for the ground), works by improving the problematic soil in situ, meaning the existing ground is strengthened and consolidated, allowing load transfer to occur through the improved native soil rather than requiring replacement.

Why do engineers select mini-piles for deep or weak ground conditions?

Engineers select mini-piles (also known as micropiles) for deep or weak ground conditions because they offer an efficient, versatile, and cost-effective solution when traditional deep foundation systems are not feasible or cost-effective. These small-diameter piles are particularly effective in challenging, poor, unstable, or weak soil compositions, where they provide stability and support without the risk of undermining the ground, a frequent issue with traditional bored piles that remove too much existing material. Furthermore, mini-piling is a foundation solution ideal for sites with logistical constraints; its typically smaller diameter (ranging from 100mm to 300mm) and corresponding smaller equipment allow for installation in confined spaces, restricted access areas, limited headroom, basements, and urban refurbishment projects.