Mini-piled underpinning strengthens basement foundations by transferring structural loads from weak surface soils to deeper, more stable layers. Small-diameter piles driven to significant depths create new load paths that reinforce the existing footing, control settlement, and protect the structure from long-term distortion or failure. This method delivers reliable stability in variable soil conditions and restricted-access sites where traditional underpinning is unsuitable.

Safe installation depends on engineered planning, controlled pile installation, and strict compliance with testing standards. Detailed documentation, phased sequencing, and continuous monitoring ensure that the foundation remains stable and meets regulatory requirements. Mini-piled underpinning also supports basement lowering and structural extensions by providing deep, stable anchorage with minimal disruption, enabling secure expansion and long-term structural performance.

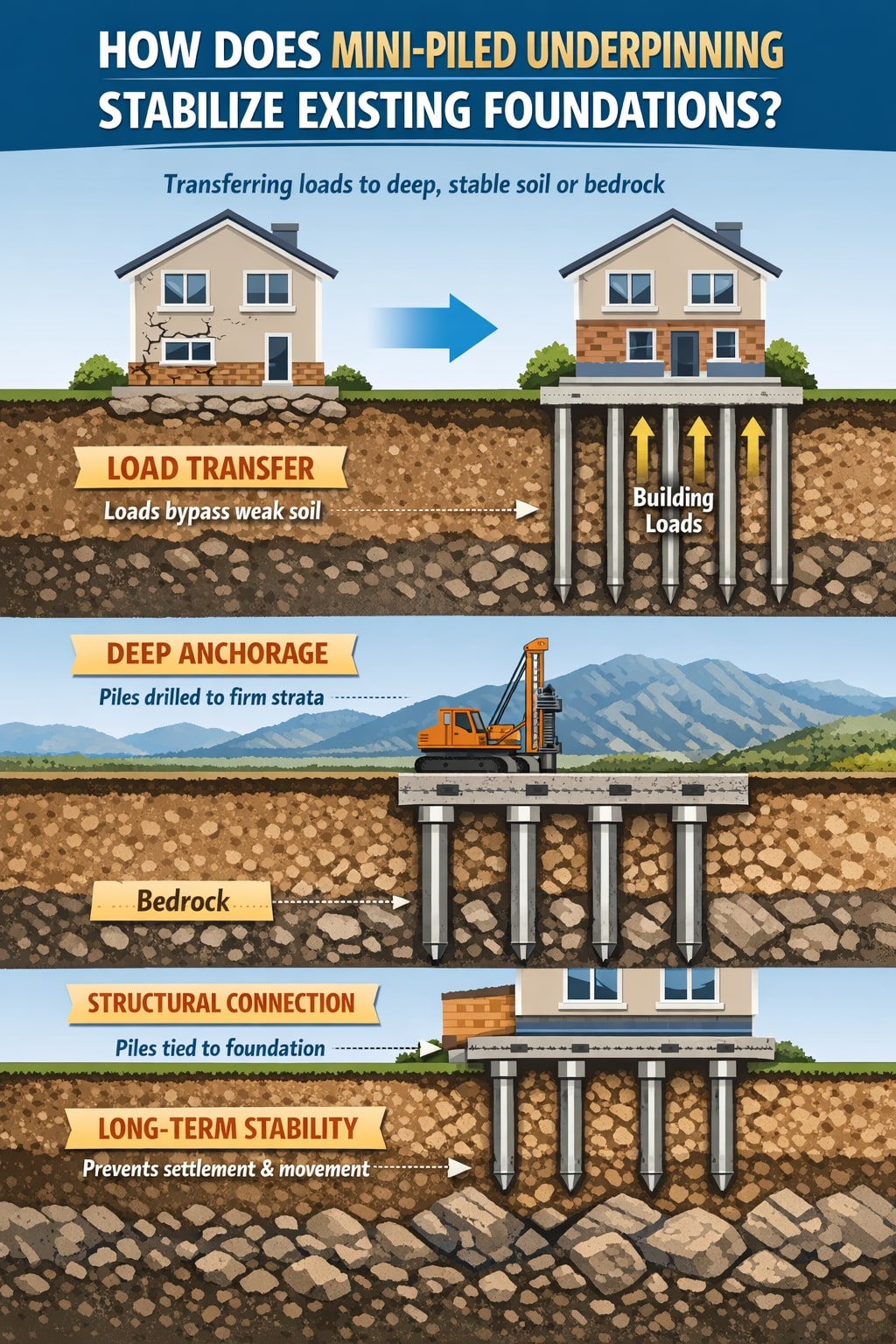

How does mini-piled underpinning stabilize existing foundations?

Mini-piled underpinning stabilizes existing foundations by installing deep piles that deliver solid support when structures rest on weak soil. The method strengthens the footing by creating new load paths that reach stable ground. The process drives mini-piles to depths of up to 15 meters until they reach a competent stratum.

These piles act as new support columns that carry structural loads away from unreliable soil. The system reinforces the foundation, redistributes weight across deeper layers, and increases overall structural integrity. Deep anchoring into stable ground ensures reliable long-term performance. The upgraded load-bearing system protects the structure from settlement, distortion, and foundation-related failure.

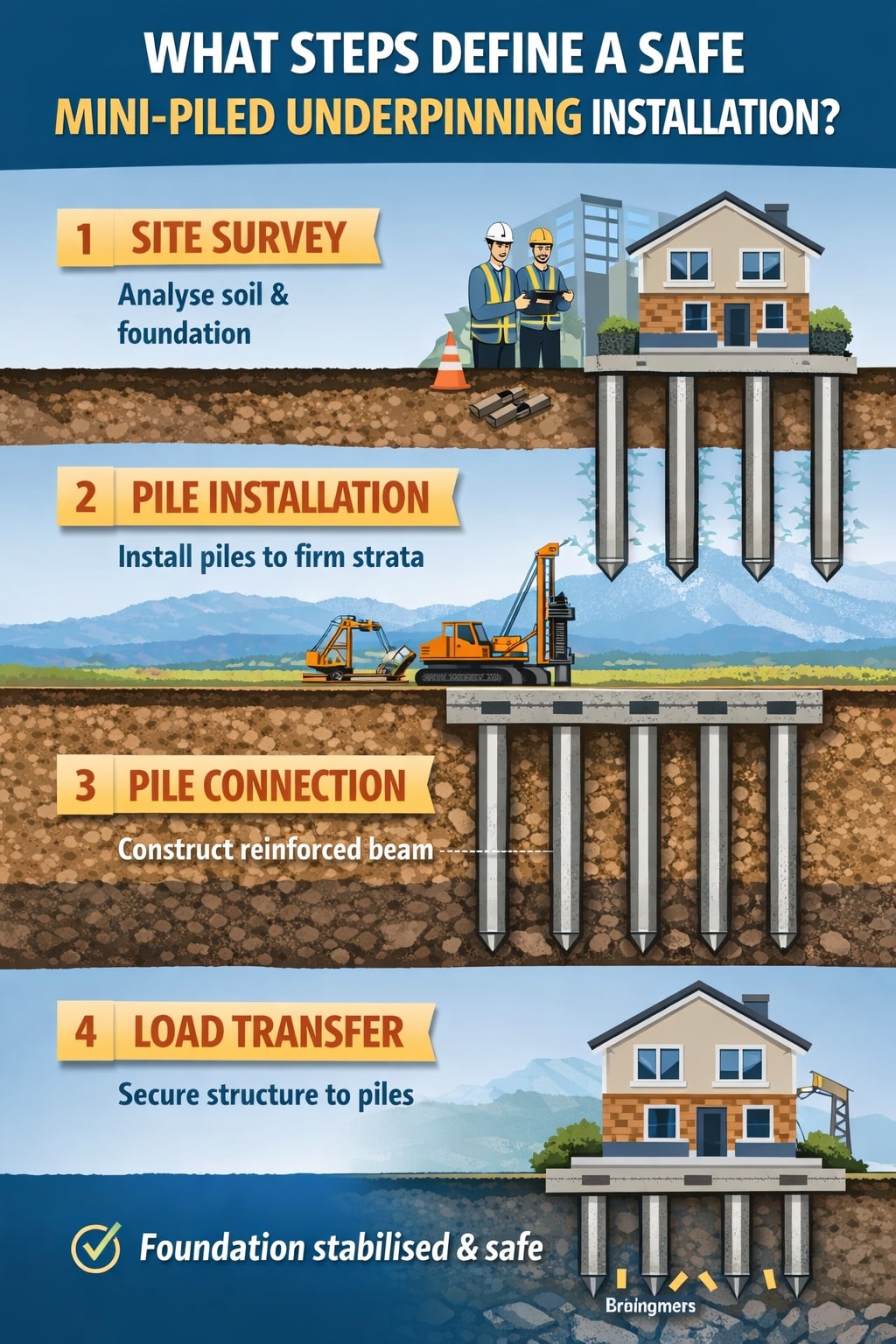

What steps define a safe mini-piled underpinning installation?

Safe mini-piled underpinning relies on structured planning, controlled installation, and continuous verification to ensure the foundation remains stable. The process starts with comprehensive documentation that maps the existing structure, foundation layout, underpinning phases, and the depth of nearby buildings. Installation follows with drilling small-diameter piles beneath the foundation, then filling them with concrete to create new load-bearing supports in confined or restricted-access areas. Ongoing monitoring verifies that the foundation stops moving and achieves long-term stability.

Important steps of a safe mini-piled underpinning installation:

- Detailed structural documentation outlining existing foundations, exterior walls, and the sequence of underpinning phases.

- Assessment of adjacent structures to identify the depth and proximity of neighbouring foundations.

- Use of small-diameter piles drilled in tight or restricted-access locations and filled with concrete.

- Creation of new load paths that reinforce the foundation without disturbing the existing structure.

- Continuous monitoring and testing to confirm halted movement and restored structural stability.

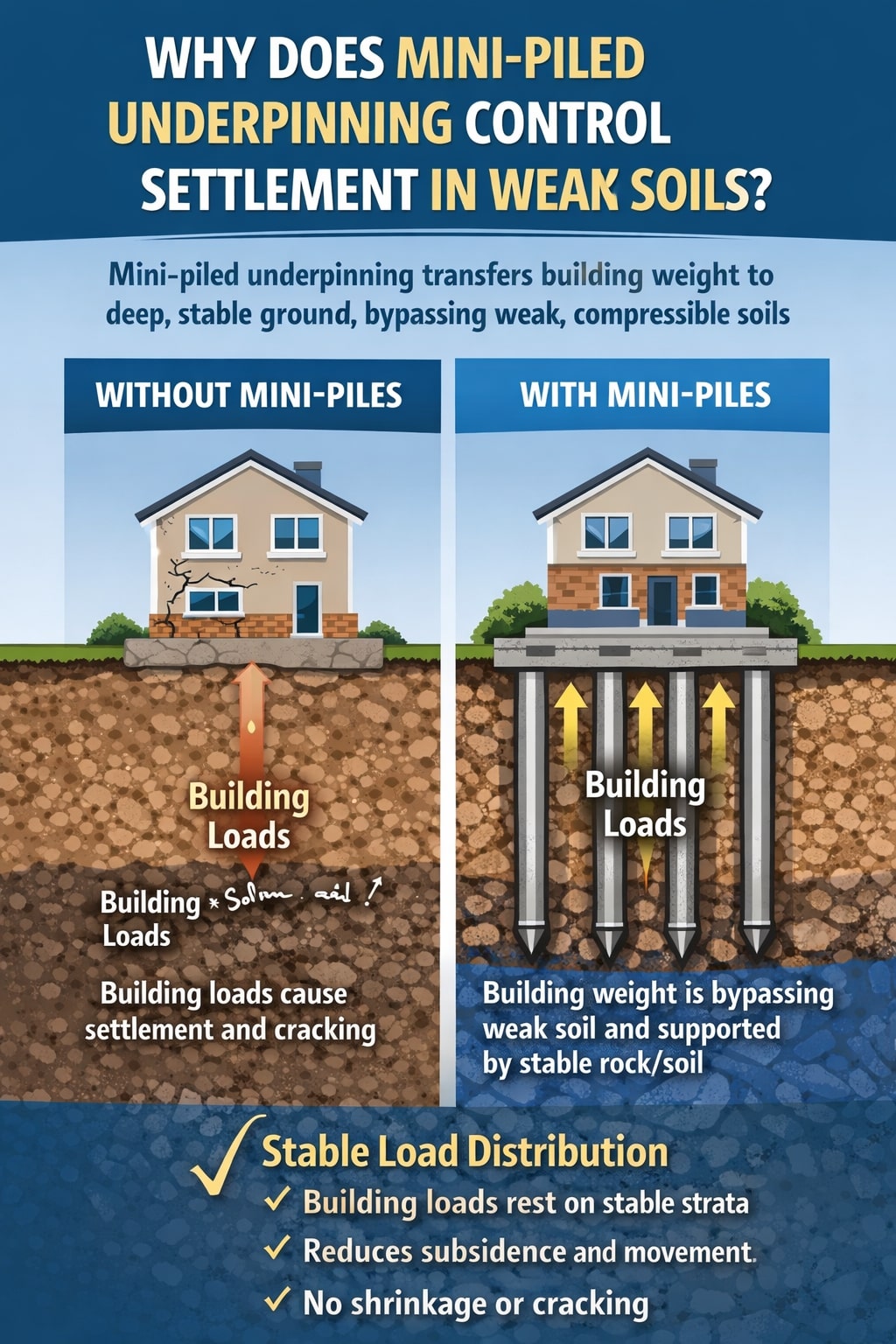

Why does mini-piled underpinning control settlement in weak soils?

Mini-piled underpinning controls settlement in weak soils because it is a modern technique designed to transfer the structural load from unstable, shallow layers to deeper, more competent soil strata or bedrock. This stabilization is achieved by installing small-diameter piles—such as steel helical or push piers—which are driven to great depths and attached to the foundation, providing discrete support points. Unlike traditional underpinning that creates new continuous concrete footings, mini-piling effectively bypasses the weak soil below the existing footing, preventing further sinking and potentially lifting the structure. This method is particularly useful when ground conditions vary, access is restricted, or when minimal excavation and structural movement are required.

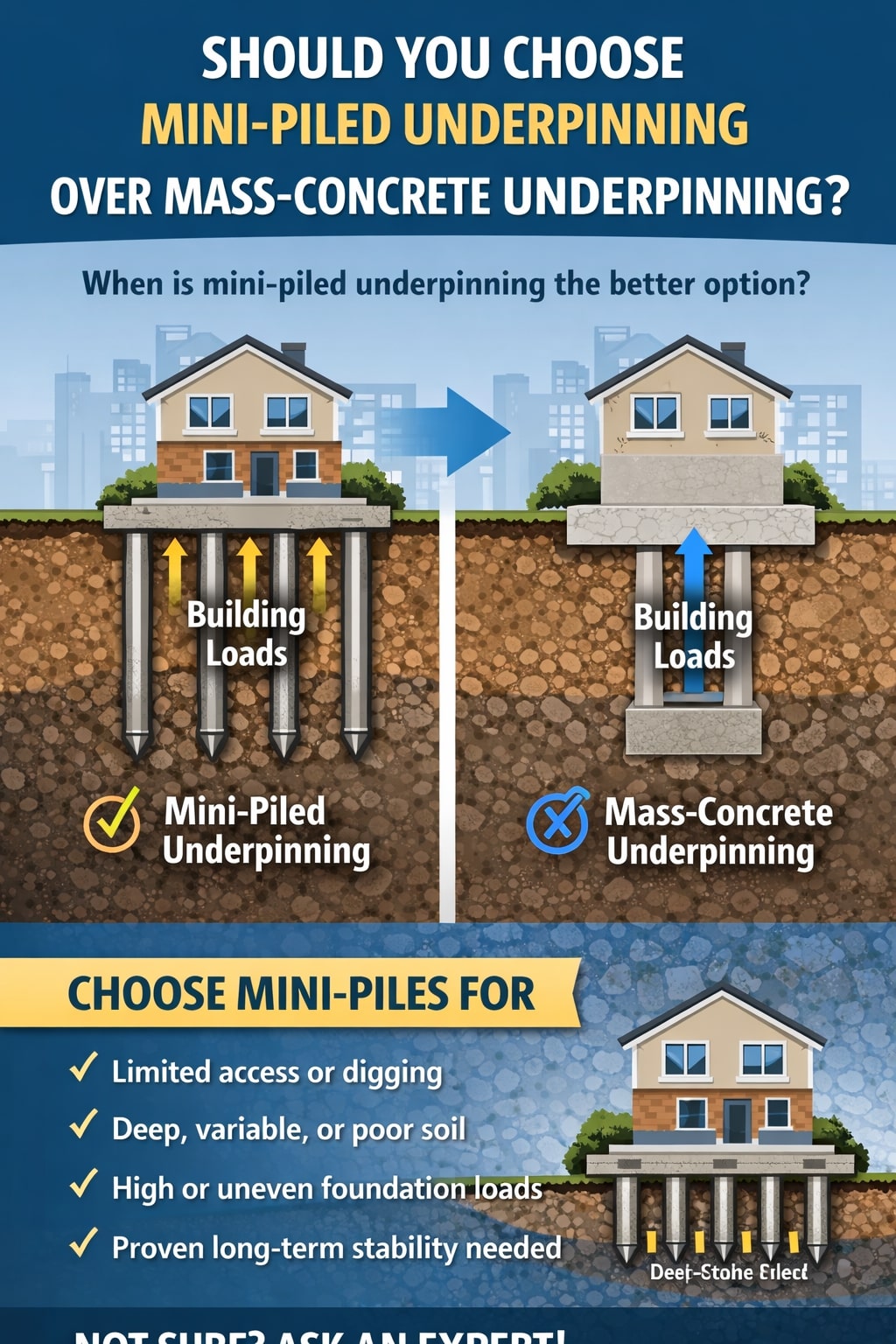

Should you choose mini-piled underpinning over mass-concrete underpinning?

The choice of mini-piled underpinning over mass-concrete underpinning (or its technically advanced beam and base adaptation) is highly recommended when specific site conditions necessitate reaching deep, stable ground layers and when access is limited.

Mini-piled underpinning is considered a more secure method and is generally chosen over traditional mass concrete due to the following key advantages and use cases:

- Access and Space Constraints: The technique is ideal for areas with limited or restrictive access and confined spaces because the necessary equipment, while requiring precise engineering, is relatively small.

- Variable Ground Conditions: It is the method of choice for sites with very variable ground conditions, as it involves driving small-diameter piles deep into the ground to reach a stable load-bearing layer, which prevents differential settlement and ensures the property remains level.

- Load Transfer Security: Mini-piling is typically the most secure method since it allows the structural weight to be transferred down to a level significantly further below the foundation than other techniques, including mass concrete.

- Environmental and Structural Sensitivity: Mini-piles have the greatest use where environmental pollution aspects are significant or where structural movements in service must be kept minimal.

How do regulations and testing validate mini-piled underpinning?

Regulations and testing validate mini-piled underpinning by requiring professional oversight for specific project scopes and mandating rigorous quality assurance procedures to confirm structural capacity and material integrity. A professional engineer’s design and field review are required for underpinning projects that involve construction below the level of adjacent footings or which exceed 1200 mm in height. This requirement mandates providing testing and reports during both the first and last stages of construction.

To guarantee long-term performance and provide confidence in the foundation’s stability, high-quality mini piling requires stringent quality assurance, verified through the following essential procedures:

- Pile load testing protocols, which verify the capacity of the installed pile systems before transferring structural loads.

- Verification of concrete strength to ensure materials adhere to standards.

- Regular inspections and adherence to quality standards during construction to reduce the likelihood of defects and future maintenance issues.

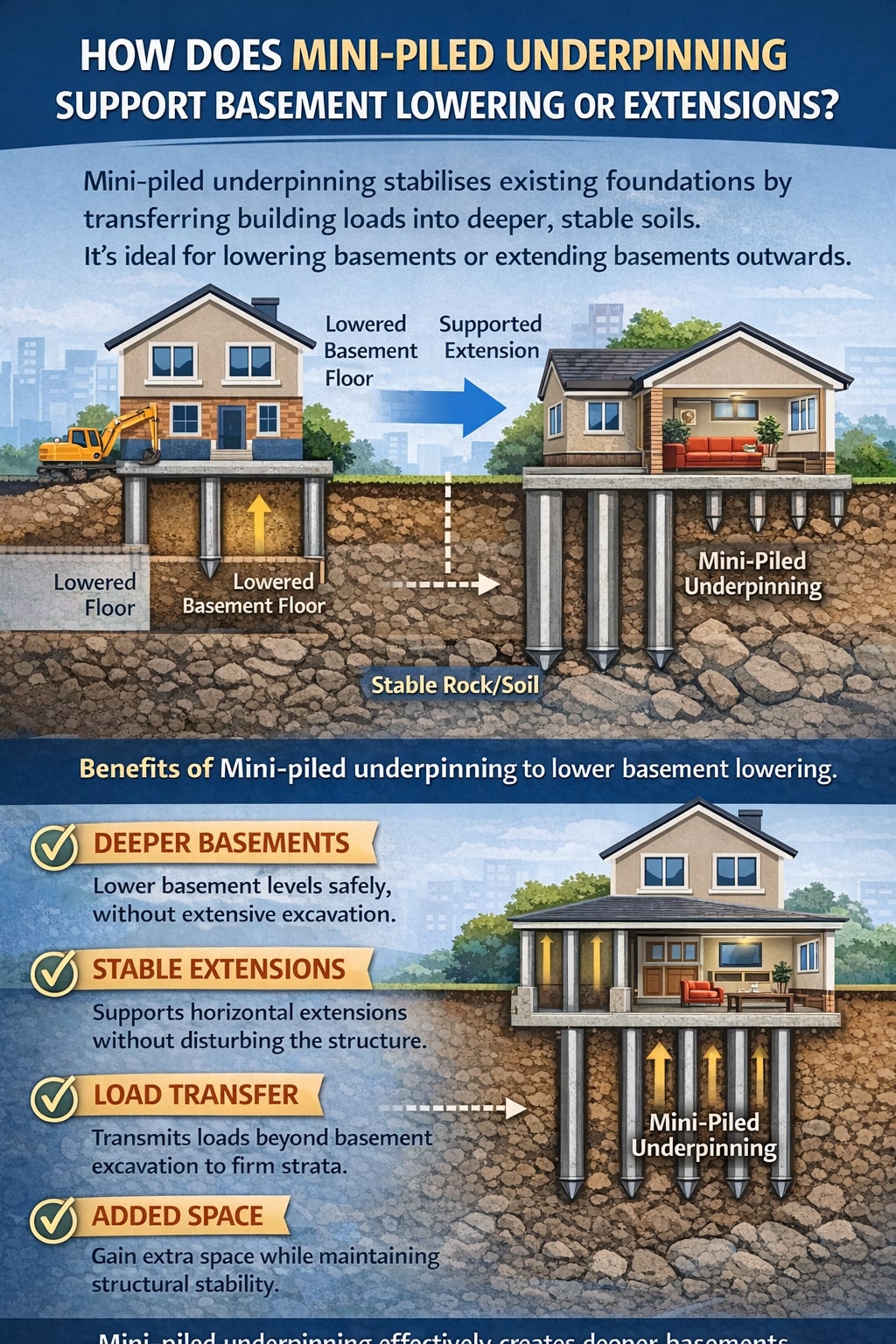

How does mini-piled underpinning support basement lowering or extensions?

Mini-piled underpinning supports basement lowering and extensions by providing robust structural reinforcement, particularly necessary for larger homes undergoing significant renovations. This technique involves driving or drilling small-diameter piles deep into the ground until they reach a stable soil layer, often reaching depths beyond 15 meters. Anchoring the structure to this stable layer prevents differential settlement, ensuring the property remains level and mitigating the risk of structural damage.

This method is highly effective for structural support due to the following key advantages:

- It is highly adaptable, supporting structures in a variety of soil conditions, including those that are unsuitable or too variable for traditional underpinning methods.

- The technique is minimally invasive, reducing disruption and preserving existing structures, while providing robust support for heavier buildings.

- It is ideal for areas with limited access or tight spaces where traditional machinery cannot operate efficiently.

How do other underpinning systems compare with mini-piled underpinning?

The comparison of other underpinning systems with mini-piled underpinning highlights differences in application, installation efficiency, and suitability based on site conditions and existing foundation needs.

Mini-piled underpinning is a modern and versatile technique that uses small-diameter piles drilled deep into the soil and reinforced with steel and concrete. It stands out for its relatively minimal equipment requirements, efficient installation process, ability to work in confined spaces, and capacity to bear immediate loads. This method has the greatest use where:

- Ground conditions are very variable.

- Access is restrictive.

- Environmental pollution aspects are significant.

- Structural movements in service must be minimal.

Other underpinning methods offer distinct advantages and drawbacks when compared to mini-piling:

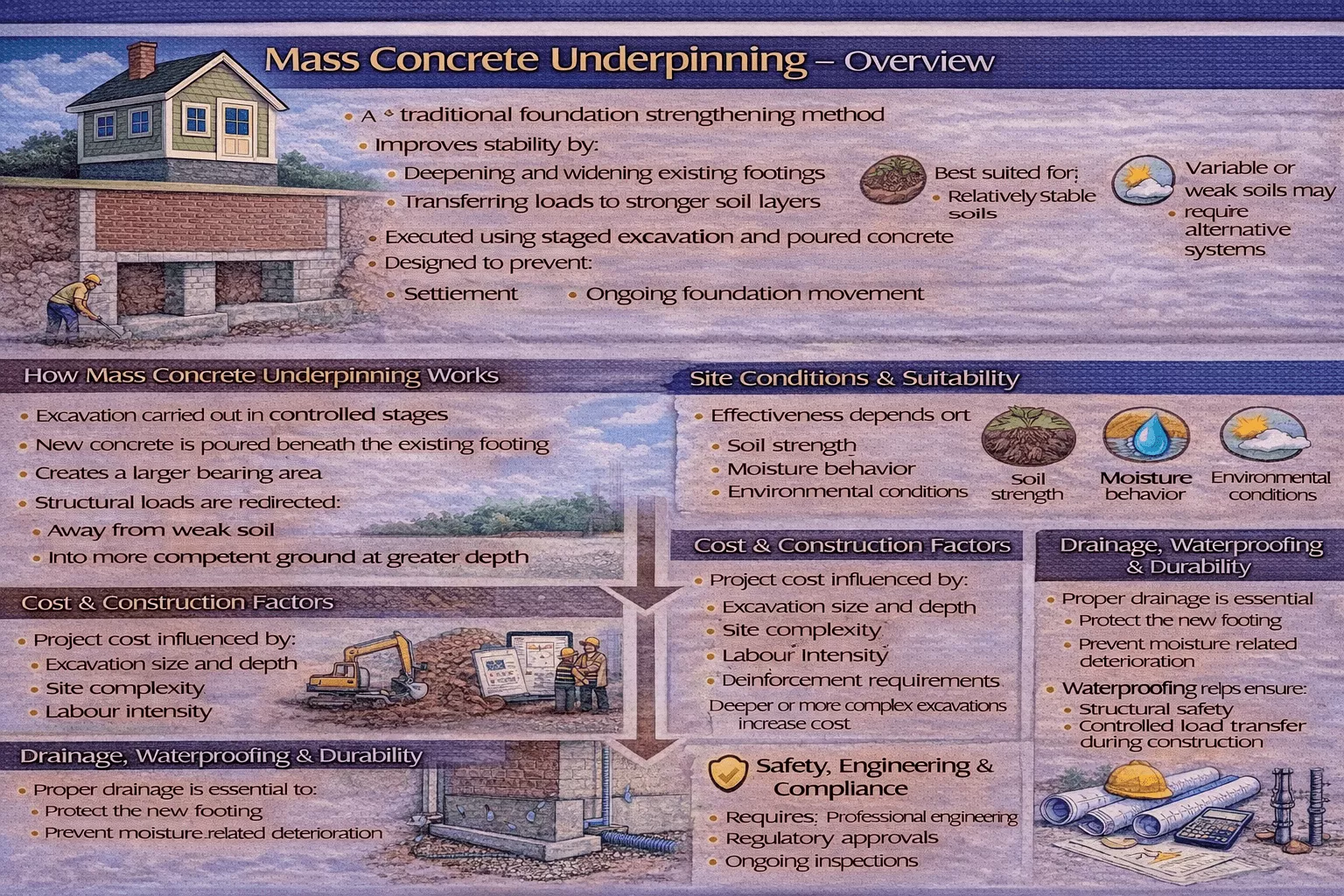

- Mass Concrete Underpinning: This is a more traditional method. Mini-piles are often preferred over traditional mass concrete underpinning because mini-piles feature a more efficient installation process and can bear immediate loads more quickly.

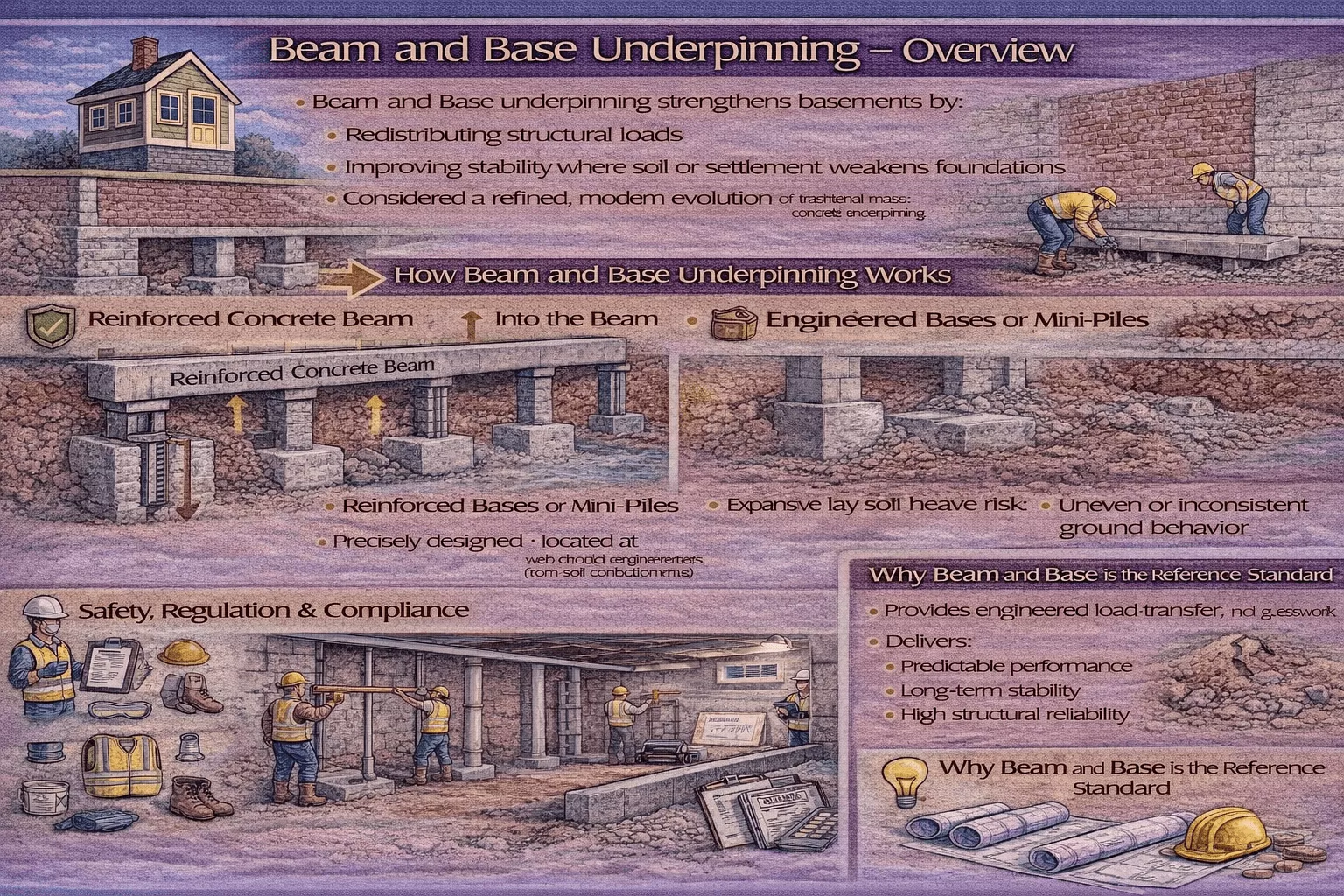

- Beam and Base Underpinning: This is a technically advanced adaptation of traditional mass concrete underpinning. It involves constructing a reinforced concrete beam—below, above, or replacing the existing footing—which transfers the building’s load to strategically located mass concrete bases. Unlike the versatile and less site-dependent mini-piles, the size and depth of the bases, as well as the beam design, are heavily dependent upon prevailing ground conditions, building configuration, and applied loads. This method often incorporates anti-heave precautions for schemes where potential expansion of clay soils may occur.

It is important to note that while all underpinning methods (including mini-piled, beam and base, and mass concrete) are ideal for stabilizing and strengthening existing foundations, general piling is typically utilized for new constructions and buildings on weak or unstable soils.

Why do site and access limits increase mini-piled underpinning costs?

Site and access limits increase mini-piled underpinning costs because restricted movement elevates both the complexity and labour requirements of an already expensive process. Limited access, which is often encountered in dense urban areas or smaller residential settings, significantly impacts the project’s budget and complexity. It makes it challenging for construction crews to bring in the necessary equipment and materials, leading to increased labour costs and an extended timeline for project completion.

Mini-piled underpinning is generally more expensive than traditional methods (such as mass concrete) due to the necessity of specialized equipment and expertise. When site constraints are introduced, requiring crews to maneuver specialized equipment in restricted spaces, this inherent cost is exacerbated. Consequently, mini-piles are often deemed less ideal for smaller residential projects solely because of the amplified expense associated with these logistical challenges.

Why is risk control and monitoring essential when mini-piled underpinning is used?

Risk control and monitoring are essential when mini-piled underpinning is used because underpinning represents major structural work that requires professional expertise and careful safety management. While mini-piled underpinning is an effective technique specifically designed to prevent differential settlement and subsequent structural damage by driving small-diameter piles deep into the ground to reach a stable layer—a method often utilized in areas with variable ground conditions or limited access—the critical nature of stabilizing the property necessitates continuous risk control and monitoring to ensure the successful execution and overall structural integrity of the complex stabilization process.

Why do long-term checks matter for mini-piled underpinning performance?

The reasons why long-term checks matter for mini-piled underpinning performance are multifaceted, focusing on proactive maintenance and ensuring enduring structural integrity. Regular monitoring and maintenance are imperative to guarantee the stability of the foundation and identify potential issues early, preventing major problems and costly repairs down the line. This proactive upkeep ensures the underpinning remains effective, extends the structure’s lifespan, and confidently safeguards the building’s structural future.

Moreover, while long-term checks maintain stability, their importance is tied to the foundational need for an enduring structure, which begins with vital steps like soil testing. Initial soil testing provides the necessary data to design a foundation that can withstand unique soil challenges, ensuring structural integrity and long-term stability. By prioritizing ongoing monitoring, homeowners and builders avoid the pitfalls of poorly supported foundations, which is essential for a successful and enduring underpinning project.